Neodymium (Nd-Fe-B) hlau nplaumyog ib hom hlau nplaum uas tsis tshua muaj hauv ntiaj teb muaj xws li neodymium (Nd), hlau (Fe), boron (B), thiab cov hlau hloov pauv.Lawv muaj kev ua tau zoo tshaj plaws hauv cov ntawv thov vim lawv qhov chaw sib nqus muaj zog, uas yog 1.4 teslas (T), chav tsev ntawm cov hlau nplaum induction lossis flux ntom.

Neodymium hlau nplaum yog categorized raws li lawv tsim, uas yog sintered los yog bonded.Lawv tau dhau los ua cov hlau nplaum siv dav tshaj plaws txij li lawv txoj kev loj hlob hauv xyoo 1984.

Nyob rau hauv nws lub xeev ntuj, neodymium yog ferromagnetic thiab tsuas yog magnetized ntawm qhov kub tsis tshua muaj neeg.Thaum nws ua ke nrog lwm cov hlau, xws li hlau, nws tuaj yeem sib nqus ntawm chav tsev kub.

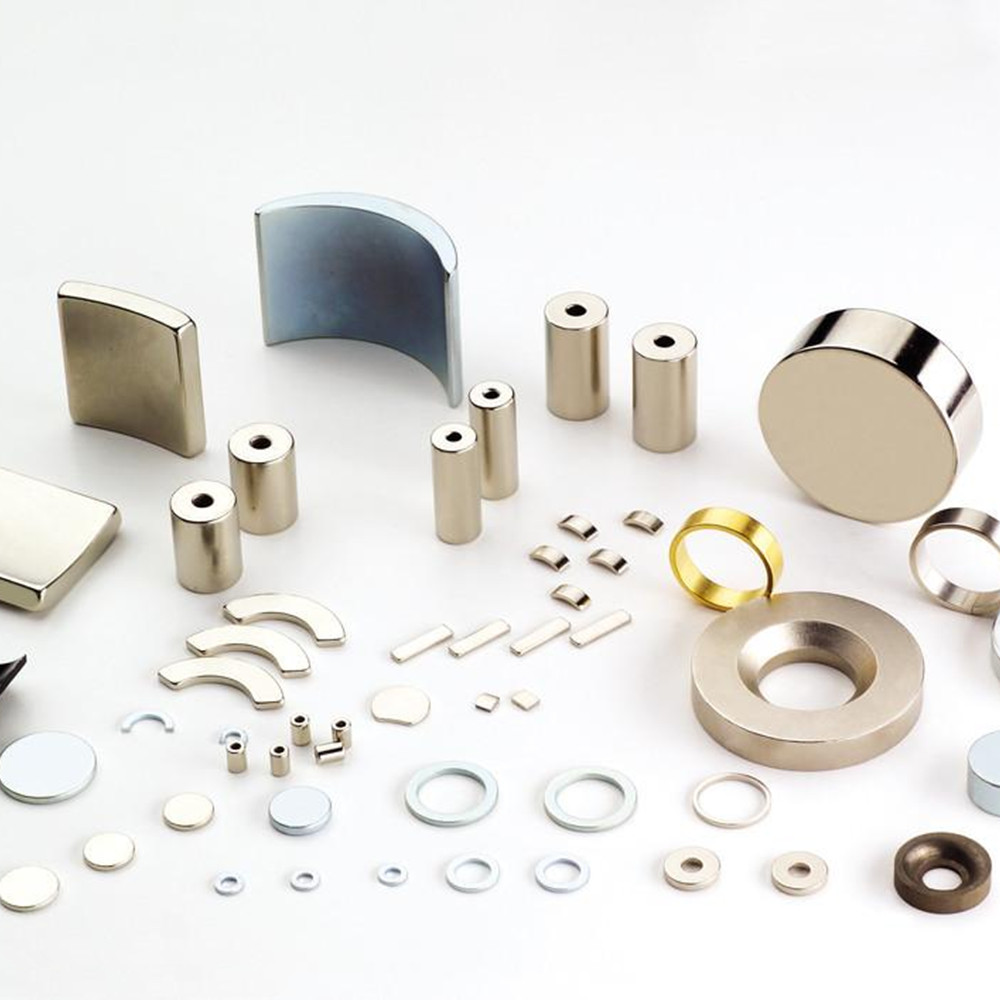

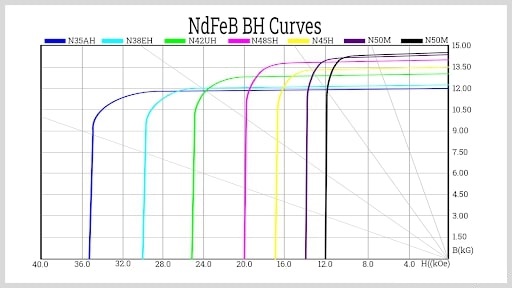

Lub peev xwm sib nqus ntawm cov hlau nplaum neodymium tuaj yeem pom hauv daim duab ntawm sab xis.

Ob hom hlau nplaum tsis tshua muaj hauv ntiaj teb yog neodymium thiab samarium cobalt.Ua ntej qhov kev tshawb pom ntawm neodymium hlau nplaum, samarium cobalt hlau nplaum tau siv ntau tshaj plaws tab sis tau hloov los ntawm cov hlau nplaum neodymium vim qhov kev siv nyiaj ntawm kev tsim cov hlau nplaum samarium cobalt.

Dab tsi yog Cov Khoom Ntawm Neodymium Magnet?

Cov yam ntxwv tseem ceeb ntawm cov hlau nplaum neodymium yog lawv muaj zog npaum li cas rau lawv qhov loj.Lub magnetic teb ntawm neodymium hlau nplaum tshwm sim thaum lub magnetic teb yog siv rau nws thiab lub atomic dipoles dlhos, uas yog lub sib nqus hysteresis voj.Thaum lub magnetic teb raug tshem tawm, ib feem ntawm qhov kev sib dhos tseem nyob hauv cov hlau nplaum neodymium.

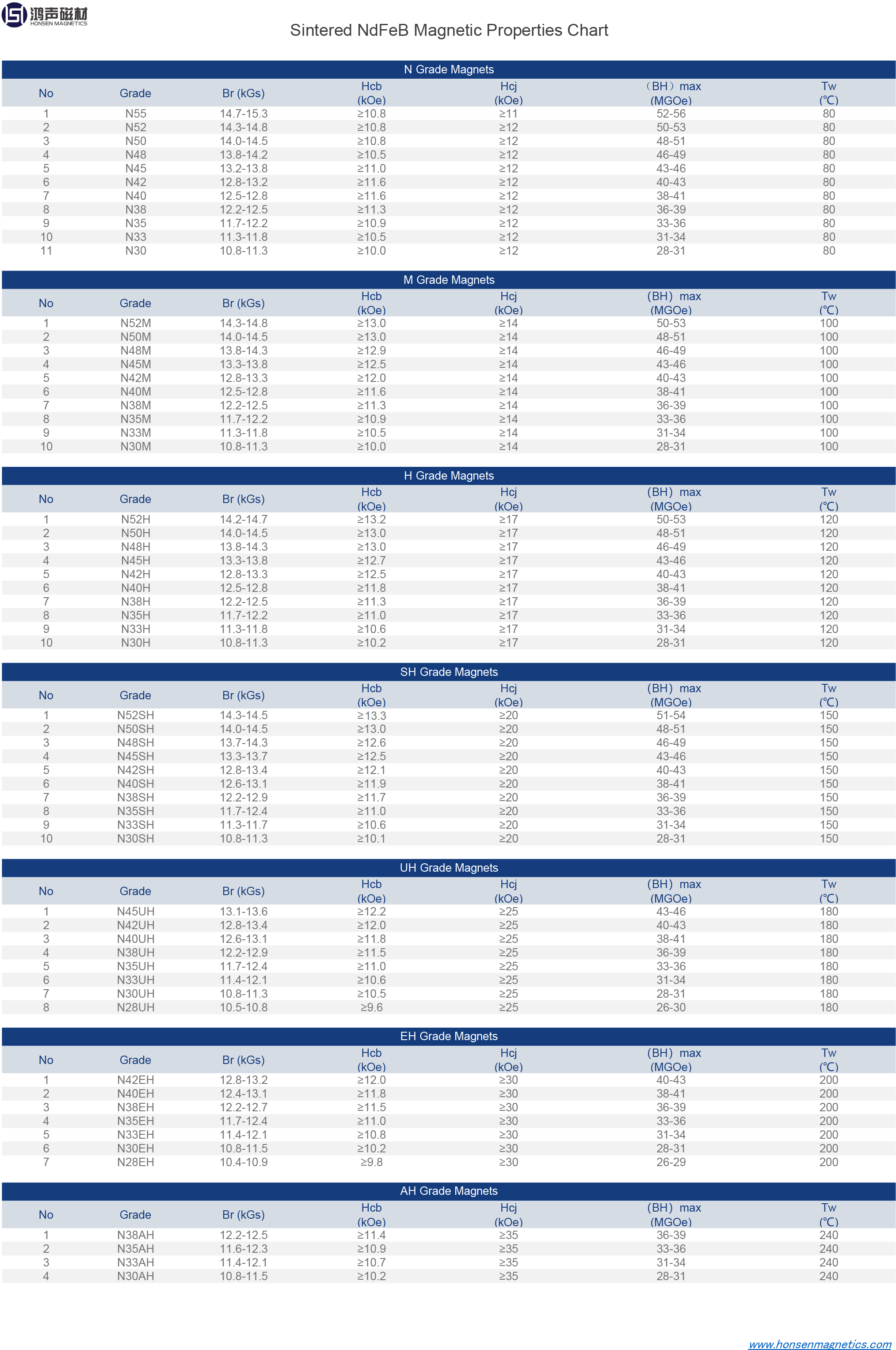

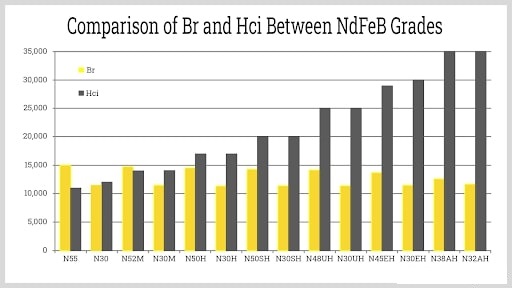

Cov qib ntawm cov hlau nplaum neodymium qhia lawv lub zog sib nqus.Qhov siab dua tus lej, qhov muaj zog yog cov hlau nplaum lub zog.Cov naj npawb los ntawm lawv cov khoom tau hais tias mega gauss Oersteds lossis MGOe, uas yog qhov muaj zog tshaj plaws ntawm nws qhov BH Curve.

Qhov ntsuas "N" pib ntawm N30 thiab mus rau N52, txawm tias N52 cov hlau nplaum tsis tshua siv lossis tsuas yog siv tshwj xeeb.Tus lej "N" tuaj yeem ua raws li ob tsab ntawv, xws li SH, uas qhia cov hlau nplaum coercivity (Hc).Qhov siab dua Hc, qhov kub siab dua qhov neo hlau nplaum tuaj yeem tiv taus ua ntej nws poob nws cov zis.

Daim ntawv qhia hauv qab no teev cov qib feem ntau ntawm cov hlau nplaum neodymium tam sim no siv.

Cov khoom ntawm Neodymium Magnets

Remanence:

Thaum neodymium muab tso rau hauv ib qho chaw sib nqus, cov atomic dipoles sib dhos.Tom qab raug tshem tawm ntawm daim teb, ib feem ntawm qhov kev sib dhos tseem tsim cov hlau nplaum neodymium.Remanence yog qhov flux ceev uas tseem tshuav thaum sab nraud teb rov qab los ntawm tus nqi ntawm saturation mus rau xoom, uas yog qhov seem magnetization.Qhov siab dua qhov remanence, qhov ntau dua qhov flux ceev.Neodymium hlau nplaum muaj qhov ntom ntom ntawm 1.0 txog 1.4 T.

Lub remanence ntawm neodymium hlau nplaum txawv nyob ntawm seb lawv ua li cas.Sintered neodymium hlau nplaum muaj T ntawm 1.0 txog 1.4.Bonded neodymium hlau nplaum muaj 0.6 txog 0.7 T.

Coercivity:

Tom qab neodymium magnetized, nws tsis rov qab mus rau xoom magnetization.Txhawm rau kom nws rov qab mus rau xoom magnetization, nws yuav tsum tau tsav rov qab los ntawm qhov chaw nyob rau hauv qhov kev taw qhia, uas yog hu ua coercivity.Cov cuab yeej ntawm cov hlau nplaum no yog nws lub peev xwm los tiv thaiv kev cuam tshuam ntawm lub zog sib nqus sab nraud yam tsis tau demagnetized.Coercivity yog qhov kev ntsuas ntawm qhov kev siv zog uas xav tau los ntawm qhov chaw sib nqus los txo qhov kev sib nqus ntawm cov hlau nplaum rov qab mus rau xoom lossis qhov tsis kam ntawm cov hlau nplaum kom demagnetized.

Coercivity yog ntsuas nyob rau hauv oersted los yog ampere units sau li Hc.Lub coercivity ntawm neodymium hlau nplaum nyob ntawm seb lawv tsim li cas.Sintered neodymium hlau nplaum muaj coercivity ntawm 750 Hc txog 2000 Hc, thaum sib txuas neodymium hlau nplaum muaj coercivity ntawm 600 Hc txog 1200 Hc.

Khoom siv zog:

Qhov ceev ntawm lub zog sib nqus yog tus cwj pwm los ntawm tus nqi siab tshaj plaws ntawm flux ceev lub sij hawm lub zog magnetic teb, uas yog tus nqi ntawm magnetic flux ib chav tsev ntawm qhov chaw.Cov chav nyob yog ntsuas hauv teslas rau SI units thiab nws Gauss nrog lub cim rau flux density yog B. Sib nqus flux ntom yog qhov sib npaug ntawm sab nraud magnetic teb H thiab lub cev sib nqus magnetic polarization J hauv SI units.

Cov hlau nplaum tas mus li muaj B teb hauv lawv qhov tseem ceeb thiab ib puag ncig.Kev taw qhia ntawm B teb lub zog yog ntaus nqi rau cov ntsiab lus sab hauv thiab sab nraud ntawm cov hlau nplaum.Ib rab koob koob hauv B teb ntawm ib lub hlau nplaum taw qhia nws tus kheej mus rau qhov kev taw qhia.

Tsis muaj txoj hauv kev yooj yim los xam cov flux ceev ntawm cov duab sib nqus.Muaj cov khoos phis tawj uas tuaj yeem ua rau suav.Cov qauv yooj yim tuaj yeem siv rau cov duab geometry tsawg.

Qhov sib nqus ntawm qhov sib nqus yog ntsuas hauv Gauss lossis Teslas thiab yog qhov kev ntsuas dav dav ntawm cov hlau nplaum lub zog, uas yog ntsuas qhov ntom ntawm nws cov magnetic teb.Lub gauss meter yog siv los ntsuas cov hlau nplaum qhov flux ceev.Lub flux ceev rau ib tug neodymium hlau nplaum yog 6000 Gauss los yog tsawg dua vim hais tias nws muaj ib tug ncaj kab demagnetization nkhaus.

Curie Kub:

Curie kub, los yog curie point, yog qhov kub ntawm cov khoom sib nqus muaj qhov hloov pauv hauv lawv cov khoom sib nqus thiab ua paramagnetic.Hauv cov hlau nplaum sib nqus, cov atoms sib nqus tau ua raws tib txoj kev coj thiab txhawb kev sib nqus sib nqus.Nce qhov kub curie hloov qhov kev npaj ntawm cov atoms.

Coercivity nce thaum kub nce.Txawm hais tias cov hlau nplaum neodymium muaj siab coercivity nyob rau hauv chav tsev kub, nws mus down raws li qhov kub nce mus txog rau thaum nws ncav cuag curie kub, uas yuav nyob ib ncig ntawm 320 ° C los yog 608 ° F.

Txawm hais tias cov hlau nplaum neodymium muaj zog npaum li cas, qhov kub thiab txias tuaj yeem hloov pauv lawv cov atoms.Kev raug kub ntev ntev tuaj yeem ua rau lawv poob lawv cov khoom sib nqus, uas pib ntawm 80 ° C lossis 176 ° F.

Neodymium Magnets Ua li cas?

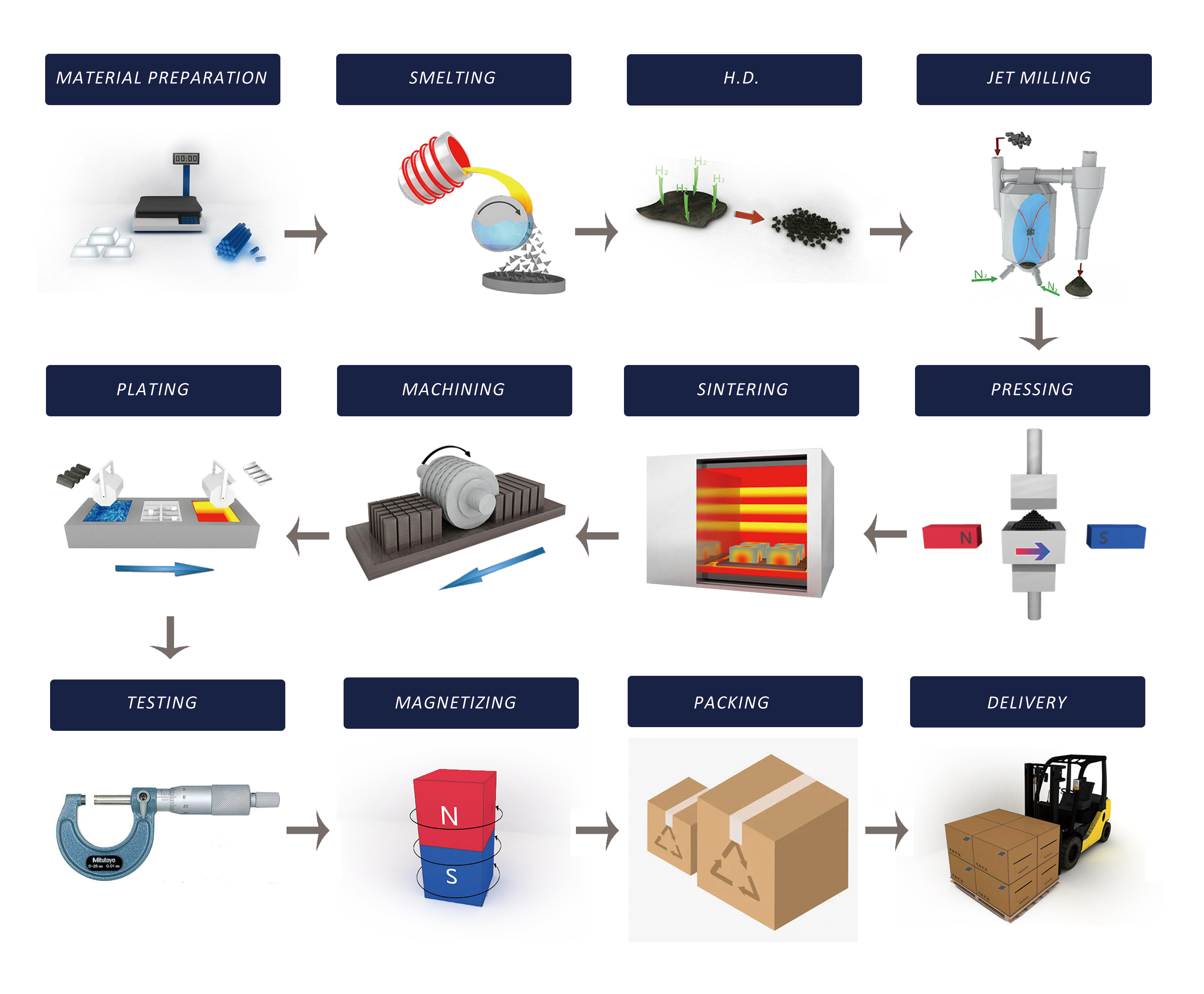

Ob txheej txheem siv los tsim cov hlau nplaum neodymium yog sintering thiab bonding.Cov khoom ntawm cov hlau nplaum tiav lawm txawv nyob ntawm seb lawv yuav ua li cas nrog sintering yog qhov zoo tshaj plaws ntawm ob txoj kev.

Yuav Ua Li Cas Neodymium Magnets

Sintering

-

Melting:

Lub Neodymium, Hlau thiab Boron yog ntsuas tawm thiab muab tso rau hauv lub tshuab nqus tsev induction rauv los tsim cov hlau.Lwm cov ntsiab lus tau ntxiv rau cov qib tshwj xeeb, xws li cobalt, tooj liab, gadolinium, thiab dysprosium los pab tiv thaiv corrosion.Cov cua sov yog tsim los ntawm cov hluav taws xob eddy tam sim no hauv lub tshuab nqus tsev kom tsis txhob muaj kab mob.Qhov sib xyaw neo alloy sib txawv rau txhua qhov chaw tsim khoom thiab qib ntawm neodymium hlau nplaum.

-

Hmoov:

Lub melted alloy yog txias thiab tsim rau hauv ingots.Cov ingots yog dav hlau milled nyob rau hauv ib tug nitrogen thiab argon cua los tsim ib tug micron-loj hmoov.Cov hmoov neodymium yog muab tso rau hauv lub hopper rau nias.

-

Nias:

Cov hmoov yog nias rau hauv qhov tuag me ntsis loj dua li qhov xav tau los ntawm cov txheej txheem hu ua kev ntxhov siab ntawm qhov kub ntawm li 725 ° C. Cov duab loj ntawm cov tuag tso cai rau shrinkage thaum lub sij hawm sintering.Thaum lub sij hawm nias, cov khoom yog raug rau ib tug magnetic teb.Nws yog muab tso rau hauv ib tug thib ob tuag yuav tsum tau nias rau hauv ib tug wider duab los dlhos lub magnetization parallel rau cov kev taw qhia ntawm nias.Qee txoj hauv kev suav nrog cov khoom siv los tsim cov chaw sib nqus thaum nias kom haum cov khoom.

Ua ntej cov hlau nplaum nias raug tso tawm, nws tau txais cov mem tes demagnetizing tawm ntawm nws demagnetized los tsim cov hlau nplaum ntsuab, uas yooj yim crumbles thiab muaj cov khoom tsis zoo sib nqus.

-

Sintering:

Sintering, los yog frittage, compacts thiab tsim cov hlau nplaum ntsuab siv cov cua sov hauv qab nws cov ntsiab lus melting kom muab nws cov khoom sib nqus zaum kawg.Cov txheej txheem yog ua tib zoo saib xyuas hauv qhov chaw tsis muaj zog, tsis muaj oxygen.Oxides tuaj yeem rhuav tshem cov hlau nplaum neodymium kev ua haujlwm.Nws yog compressed ntawm qhov kub thiab txias mus txog 1080 ° C tab sis hauv qab nws cov ntsiab lus melting kom yuam kom cov khoom ua raws ib leeg.

Lub quench yog siv los ua kom txias cov hlau nplaum thiab txo qis theem, uas yog cov sib txawv ntawm cov hlau uas muaj cov khoom tsis zoo sib nqus.

-

Machining:

Sintered hlau nplaum yog hauv av siv pob zeb diamond lossis hlau txiav cov cuab yeej los ua kom lawv ua tau raws li qhov raug.

-

Plating thiab txheej:

Neodymium oxidizes sai thiab yooj yim rau corrosion, uas tuaj yeem tshem tawm nws cov khoom sib nqus.Raws li kev tiv thaiv, lawv tau coated nrog yas, npib tsib xee, tooj liab, zinc, tin, los yog lwm yam txheej txheej.

-

Magnetization:

Txawm hais tias cov hlau nplaum muaj cov kev taw qhia ntawm kev sib nqus, nws tsis yog hlau nplaum thiab yuav tsum tau luv luv ntawm cov hlau nplaum uas muaj zog, uas yog ib lub coil ntawm cov hlau uas nyob ib puag ncig cov hlau nplaum.Lub magnetizing muaj cov capacitors thiab high voltage los tsim ib tug muaj zog tam sim no.

-

Kev soj ntsuam zaum kawg:

Cov ntsuas digital ntsuas qhov ntsuas qhov ntev thiab x-ray fluorescence thev naus laus zis txheeb xyuas qhov tuab ntawm plating.Cov txheej txheem yog kuaj nyob rau hauv lwm txoj kev los xyuas kom meej nws zoo thiab lub zog.BH nkhaus yog kuaj los ntawm hysteresis graph kom paub meej tias tag nrho cov magnification.

Bonding

Bonding, los yog compression bonding, yog ib tug tuag nias txheej txheem uas siv ib tug sib tov ntawm neodymium hmoov thiab ib tug epoxy binding tus neeg saib xyuas.Qhov sib tov yog 97% cov khoom sib nqus thiab 3% epoxy.

Cov epoxy thiab neodymium sib tov yog compressed nyob rau hauv ib tug xovxwm los yog extruded thiab kho nyob rau hauv lub qhov cub.Txij li thaum sib tov yog nias rau hauv ib tug tuag los yog muab los ntawm extrusion, hlau nplaum yuav molded rau hauv complex duab thiab configurations.Cov txheej txheem compression bonding ua cov hlau nplaum nrog nruj tolerances thiab tsis tas yuav tsum tau ua haujlwm thib ob.

Compression bonded hlau nplaum yog isotropic thiab tuaj yeem sib nqus nyob rau hauv txhua qhov kev taw qhia, uas suav nrog ntau qhov kev teeb tsa.Lub epoxy binding ua rau cov hlau nplaum muaj zog txaus los milled los yog lathed tab sis tsis raug drilled los yog tapped.

Radial Sintered

Radially oriented neodymium hlau nplaum yog cov hlau nplaum tshiab tshaj plaws ntawm kev lag luam hlau nplaum.Cov txheej txheem tsim cov hlau nplaum radial aligned tau paub ntau xyoo tab sis tsis raug nqi.Cov kev tsim kho thev naus laus zis tsis ntev los no tau ua kom cov txheej txheem tsim khoom ua kom cov hlau nplaum sib xyaw ua kom yooj yim los tsim.

Peb cov txheej txheem rau kev tsim cov khoom siv hluav taws xob sib xyaw neodymium hlau nplaum yog anisotropic siab molding, kub nias rov qab extrusion, thiab radial rotating teb alignment.

Cov txheej txheem sintering ua kom ntseeg tau tias tsis muaj qhov tsis muaj zog hauv cov hlau nplaum.

Qhov tshwj xeeb zoo ntawm cov hlau nplaum sib xyaw radially yog cov kev taw qhia ntawm cov hlau nplaum, uas txuas mus rau ib puag ncig ntawm cov hlau nplaum.Sab qab teb ncej ntawm cov hlau nplaum yog nyob rau sab hauv ntawm lub nplhaib, thaum lub sab qaum teb ncej yog nyob rau hauv nws ncig.

Radially oriented neodymium hlau nplaum yog anisotropic thiab magnetized los ntawm sab hauv ntawm lub nplhaib mus rau sab nraud.Radial magnetization tsub kom lub nplhaib sib nqus quab yuam thiab tuaj yeem ua rau ntau yam qauv.

Radial neodymium nplhaib hlau nplaum yuav siv tau rau synchronous motors, stepping motors, thiab DC brushless motors rau lub tsheb, computer, hluav taws xob, thiab kev sib txuas lus industries.

Kev siv ntawm Neodymium Magnets

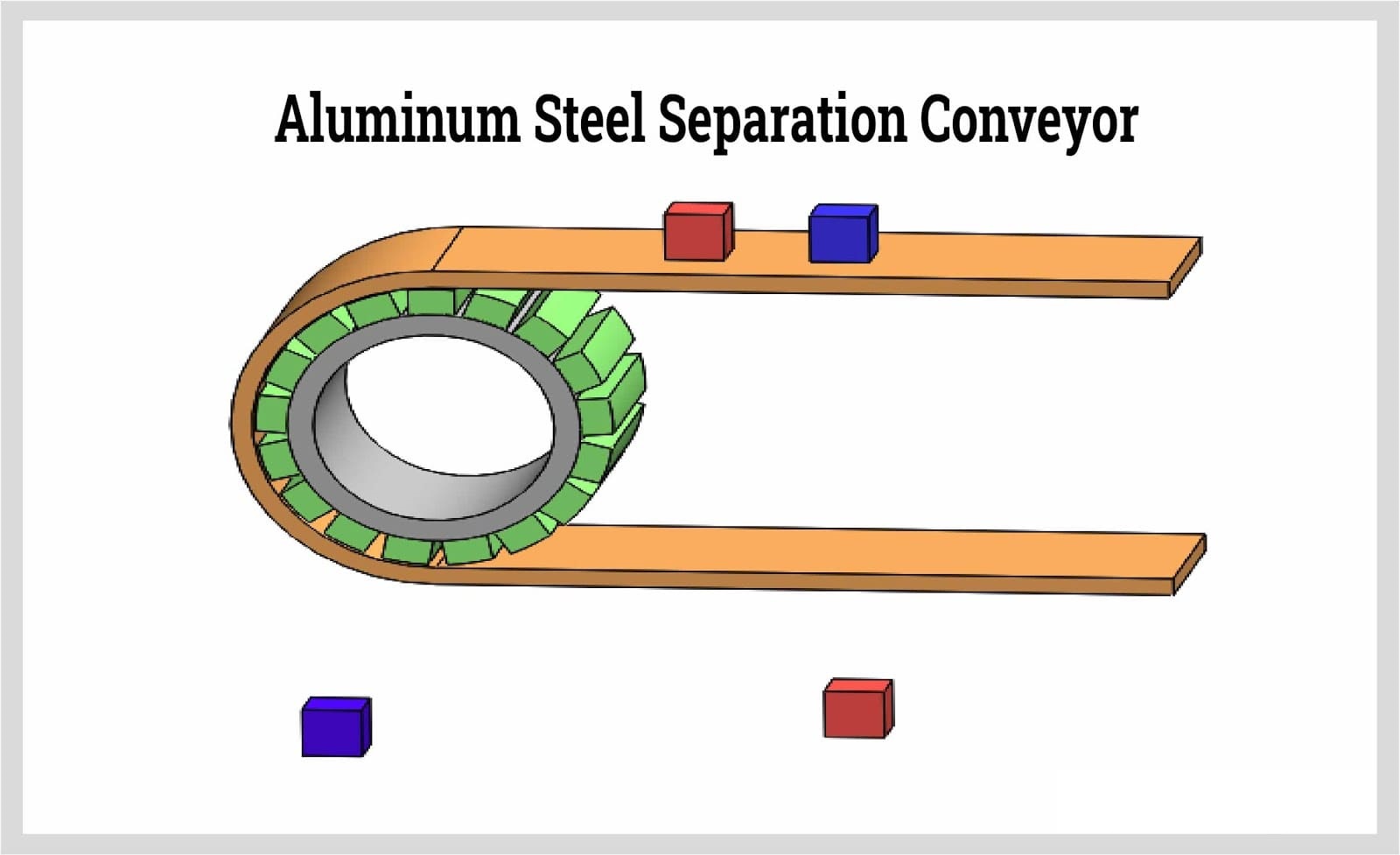

Sib Nqus Sib Nqus Conveyors:

Hauv kev ua qauv qhia hauv qab no, txoj siv conveyor yog them nrog cov hlau nplaum neodymium.Cov hlau nplaum yog teem nrog alternating ncej tig tawm uas ua rau lawv muaj zog sib nqus tuav.Tej yam uas tsis nyiam rau cov hlau nplaum poob, thaum cov khoom ferromagnetic poob rau hauv cov khoom sib sau.

Hard disk drives:

Hard drives muaj lem thiab sectors nrog magnetic cells.Cov hlwb raug magnetized thaum cov ntaub ntawv sau rau lub tsav.

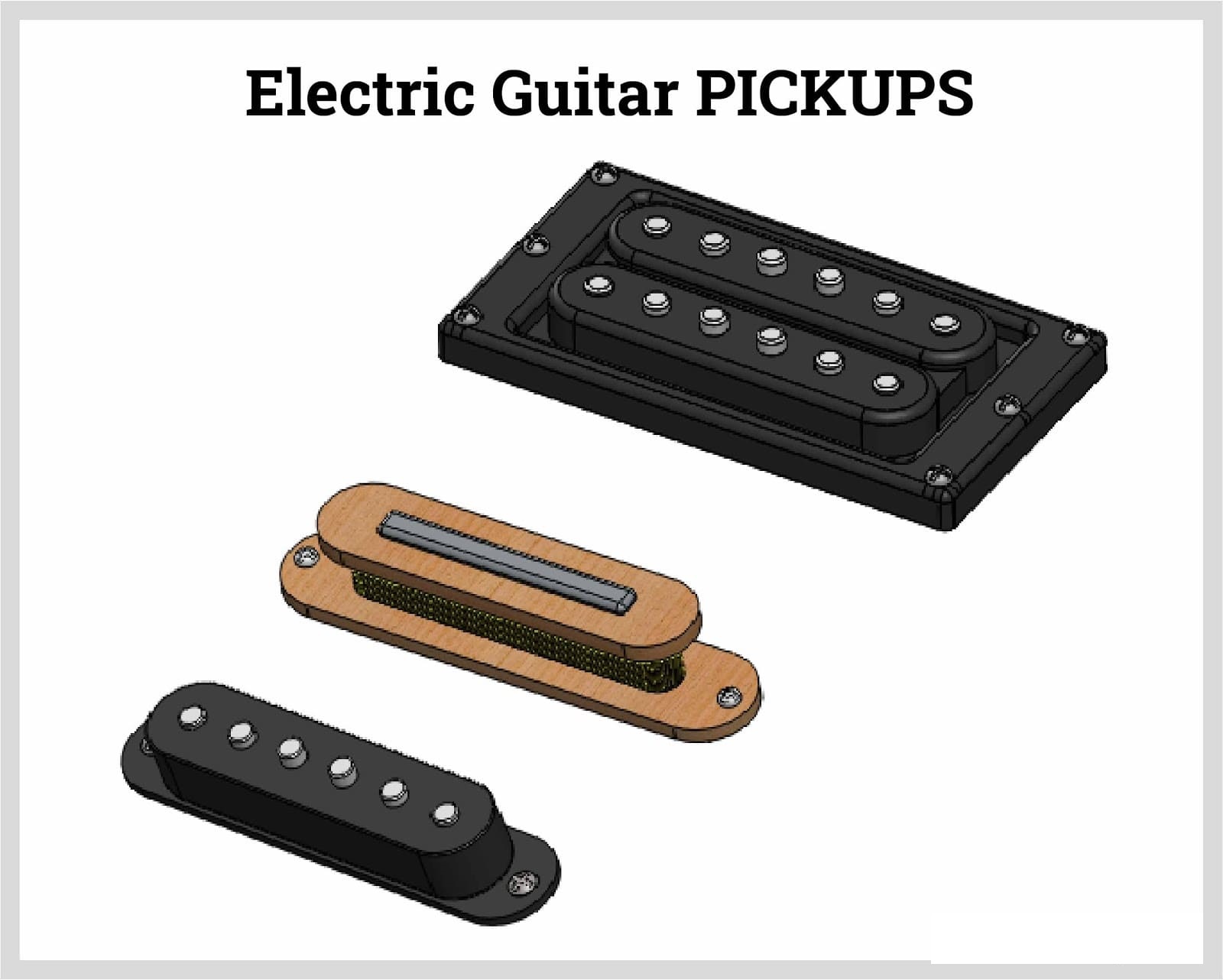

Electric Guitar Pickups:

Ib qho hluav taws xob guitar pickup hnov cov hlua vibrating thiab hloov lub teeb liab mus rau hauv hluav taws xob tsis muaj zog xa mus rau lub amplifier thiab hais lus.Hluav taws xob guitars tsis zoo li acoustic guitars uas ua kom nrov nrov hauv lub thawv hollow hauv qab cov hlua.Hluav taws xob guitars tuaj yeem yog hlau lossis ntoo nrog lawv lub suab nrov hauv hluav taws xob.

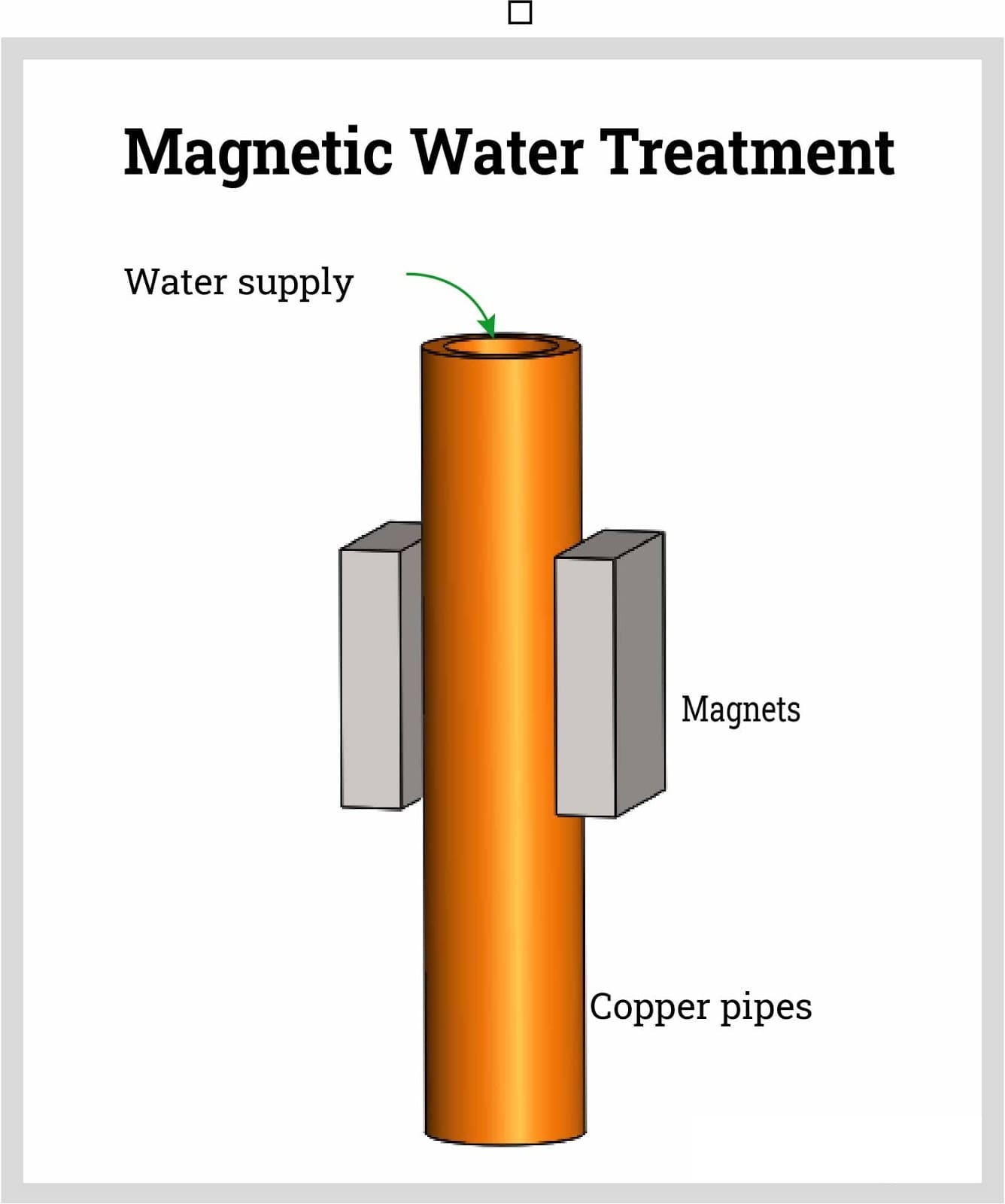

Kev kho dej:

Neodymium hlau nplaum yog siv rau hauv kev kho dej kom txo qhov scaling los ntawm cov dej tawv.Cov dej nyuaj muaj cov ntsiab lus ntawm calcium thiab magnesium.Nrog kev kho dej sib nqus, dej dhau los ntawm qhov chaw sib nqus kom ntes qhov ntsuas.Cov cuab yeej siv tsis tau tiav raws li kev siv tau zoo.Muaj cov txiaj ntsig tau txhawb nqa.

Reed Switches:

Lub reed hloov yog ib qho hluav taws xob hloov ua los ntawm ib qho chaw sib nqus.Lawv muaj ob txoj kev sib cuag thiab hlau reeds nyob rau hauv ib lub hnab ntawv iav.Cov kev sib cuag ntawm qhov hloov pauv tau qhib kom txog thaum qhib los ntawm cov hlau nplaum.

Reed keyboards yog siv nyob rau hauv txhua yam tshuab raws li qhov sib thooj sensors nyob rau hauv lub qhov rooj thiab qhov rais rau burglar tswb systems thiab tamper pov thawj.Hauv laptops, reed keyboards muab lub laptop rau hauv hom pw tsaug zog thaum lub hau kaw.Pedal keyboards rau cov yeeb nkab hauv nruab nrog cev siv cov reed keyboards uas nyob rau hauv ib lub iav enclosure rau cov neeg tiv thaiv lawv ntawm av, plua plav, thiab khib nyiab.

Sewing Magnets:

Neodymium sew nyob rau hauv cov hlau nplaum yog siv rau sib nqus clasps ntawm purses, khaub ncaws, thiab folders los yog binders.Sewing hlau nplaum yog muag nyob rau hauv khub nrog ib tug hlau nplaum yog ib tug + thiab lwm yam a-.

Hniav Magnets:

Cov hniav tuaj yeem tuav hauv qhov chaw los ntawm cov hlau nplaum kos rau hauv tus neeg mob lub puab tsaig.Cov hlau nplaum yog tiv thaiv corrosion los ntawm qaub ncaug los ntawm stainless hlau plating.Ceramic titanium nitride yog siv los tiv thaiv kev puas tsuaj thiab txo qhov raug nickel.

Magnetic Doorstops:

Sib nqus qhov rooj yog qhov chaw nres tsheb uas tuav lub qhov rooj qhib.Lub qhov rooj viav vias qhib, kov cov hlau nplaum, thiab nyob twj ywm qhib kom txog thaum lub qhov rooj rub tawm ntawm cov hlau nplaum.

Jewelry Clasp:

Sib nqus hniav nyiaj hniav kub clasps tuaj nrog ob halves thiab muag raws li ib khub.Cov halves muaj cov hlau nplaum nyob rau hauv ib lub tsev ntawm cov khoom uas tsis yog hlau nplaum.Ib lub voj hlau ntawm qhov kawg txuas cov saw ntawm ib txoj hlua los yog caj dab.Cov hlau nplaum vaj tse haum rau hauv ib leeg tiv thaiv ib sab-rau-sab lossis shearing txav ntawm cov hlau nplaum kom muaj kev tuav ruaj khov.

Cov neeg hais lus:

Cov neeg hais lus hloov hluav taws xob ua hluav taws xob ua hluav taws xob los yog lub zog.Lub tshuab hluav taws xob compresses cua thiab hloov mus rau suab zog lossis suab siab.Ib qho hluav taws xob tam sim no, xa los ntawm cov xaim hlau, tsim ib qho chaw sib nqus hauv cov hlau nplaum txuas nrog tus neeg hais lus.Lub suab coil yog attracted thiab repelled los ntawm cov hlau nplaum mus tas li, uas ua rau lub khob hliav qab, lub suab coil txuas nrog, txav rov qab thiab tawm mus.Lub cones motion tsim lub siab nthwv dej uas hnov li suab.

Anti-Lock Brake Sensors:

Nyob rau hauv kev tiv thaiv-lock brakes, neodymium hlau nplaum yog qhwv hauv tooj liab coils nyob rau hauv lub nres lub sensors.Ib qho kev tiv thaiv kev xauv lub kaw lus tswj cov nqi log nrawm thiab de-accelerate los ntawm kev tswj cov kab siab siv rau lub nres.Cov teeb liab tswj, tsim los ntawm tus maub los thiab siv rau lub nres siab modulating chav tsev, yog muab los ntawm lub log ceev sensors.

Cov hniav ntawm lub nplhaib sensor tig dhau los ntawm qhov sib nqus sensor, uas ua rau muaj kev thim rov qab ntawm polarity ntawm cov hlau nplaum uas xa cov teeb liab zaus mus rau lub kaum sab xis tshaj tawm ntawm lub qag.Qhov sib txawv ntawm lub teeb liab yog qhov acceleration ntawm lub log.

Neodymium Magnet Considerations

Raws li cov hlau nplaum uas muaj zog tshaj plaws thiab muaj zog tshaj plaws hauv ntiaj teb, cov hlau nplaum neodymium tuaj yeem ua rau muaj kev cuam tshuam tsis zoo.Nws yog ib qho tseem ceeb uas lawv yuav tsum tau saib xyuas kom zoo nrog kev xav txog qhov kev puas tsuaj uas lawv tuaj yeem ua rau.Hauv qab no yog cov lus piav qhia ntawm qee qhov tsis zoo ntawm cov hlau nplaum neodymium.

Cov teebmeem tsis zoo ntawm Neodymium Magnets

Lub cev raug mob:

Cov hlau nplaum neodymium tuaj yeem dhia ua ke thiab rub daim tawv nqaij lossis ua rau raug mob hnyav.Lawv tuaj yeem dhia lossis slam ua ke ntawm ob peb nti mus rau ob peb taw sib nrug.Yog tias tus ntiv tes nyob hauv txoj kev, nws tuaj yeem tawg lossis raug mob hnyav.Neodymium hlau nplaum muaj zog dua li lwm hom hlau nplaum.Lub zog tsis txaus ntseeg ntawm lawv feem ntau tuaj yeem xav tsis thoob.

Magnet Breakage:

Neodymium hlau nplaum yog nkig thiab tuaj yeem tev, nti, tawg lossis tawg yog tias lawv sib tsoo ua ke, uas xa cov hlau ntse me me ya mus rau qhov nrawm.Cov hlau nplaum neodymium yog ua los ntawm cov khoom tawv tawv, nkig.Txawm hais tias ua los ntawm cov hlau, thiab muaj qhov ci ntsa iab, nws yog xim hlau, lawv tsis ruaj khov.Kev tiv thaiv qhov muag yuav tsum hnav thaum tuav lawv.

Kom deb ntawm me nyuam:

Neodymium hlau nplaum tsis yog cov khoom ua si.Cov menyuam yaus yuav tsum tsis txhob raug tso cai los tuav lawv.Cov me me tuaj yeem ua rau muaj kev phom sij.Yog tias ntau cov hlau nplaum tau nqos, lawv txuas rau ib leeg los ntawm cov phab ntsa hauv cov hnyuv, uas yuav ua rau muaj teeb meem kev noj qab haus huv hnyav, yuav tsum tau phais sai sai.

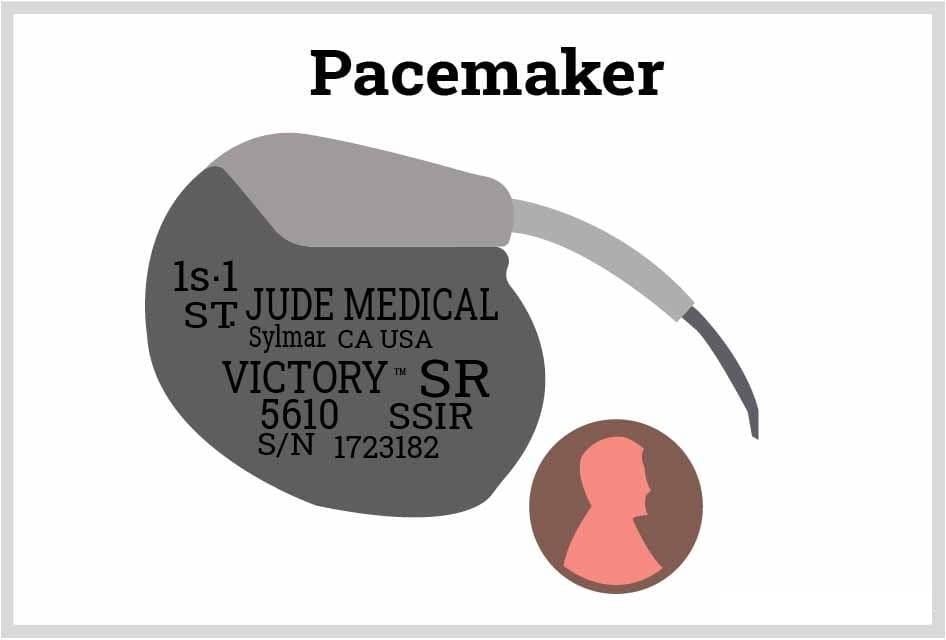

Kev phom sij rau Pacemakers:

Lub zog ntawm kaum gauss nyob ze ntawm lub tshuab pacemaker lossis defibrillator tuaj yeem cuam tshuam nrog cov khoom cog.Neodymium hlau nplaum tsim cov hlau nplaum muaj zog, uas tuaj yeem cuam tshuam nrog cov pacemakers, ICDs, thiab cov khoom siv kho mob cog.Ntau cov khoom siv cog cog tsis siv thaum lawv nyob ze ntawm qhov chaw sib nqus.

Magnetic Media:

Cov hlau nplaum muaj zog los ntawm cov hlau nplaum neodymium tuaj yeem ua rau cov hlau nplaum sib nqus xws li floppy disks, credit cards, magnetic ID cards, cassette tapes, video tapes, ua puas lub TV qub, VCRs, computer monitors, thiab CRT displays.Lawv yuav tsum tsis txhob muab tso rau ze ntawm cov khoom siv hluav taws xob.

GPS thiab Smartphones:

Sib nqus teb cuam tshuam nrog compasses lossis magnetometers thiab sab hauv compasses ntawm smartphones thiab GPS.Lub koom haum International Air Transport Association thiab Tsoom Fwv Teb Chaws Asmeskas cov cai thiab cov cai tswj hwm kev xa khoom ntawm cov hlau nplaum.

Nickel Allergy:

Yog tias koj muaj kev ua xua npib tsib xee, lub cev tiv thaiv kab mob ua yuam kev npib tsib xee ua tus neeg nkag siab txaus ntshai thiab tsim cov tshuaj los tawm tsam nws.Kev ua xua rau npib tsib xee yog qhov liab liab thiab ua pob liab liab.Nickel allergies muaj ntau dua rau cov poj niam thiab cov ntxhais.Kwv yees li, 36 feem pua ntawm cov poj niam, hnub nyoog qis dua 18, muaj kev tsis haum nickel.Txoj hauv kev kom tsis txhob ua xua npib tsib xee yog kom tsis txhob nickel coated neodymium hlau nplaum.

Demagnetization:

Cov hlau nplaum neodymium khaws lawv cov txiaj ntsig txog li 80 ° C lossis 175 ° F. Qhov kub uas lawv pib poob lawv cov txiaj ntsig txawv ntawm qib, cov duab, thiab daim ntawv thov.

Flammable:

Neodymium hlau nplaum yuav tsum tsis txhob drilled los yog machined.Cov hmoov av thiab hmoov uas ua los ntawm kev sib tsoo yog flammable.

Corrosion:

Neodymium hlau nplaum yog ua tiav nrog qee hom txheej los yog plating los tiv thaiv lawv ntawm cov khoom.Lawv tsis muaj dej tsis muaj dej thiab yuav xeb lossis xeb thaum muab tso rau hauv qhov chaw ntub dej lossis ntub dej.

Cov qauv thiab cov kev cai rau kev siv Neodymium Magnet

Txawm hais tias cov hlau nplaum neodymium muaj cov hlau nplaum muaj zog, lawv nkig heev thiab yuav tsum tau tuav tshwj xeeb.Ntau lub koom haum saib xyuas kev lag luam tau tsim cov kev cai hais txog kev tuav, tsim khoom, thiab xa khoom ntawm cov hlau nplaum neodymium.Cov lus piav qhia luv luv ntawm qee qhov kev cai muaj nyob hauv qab no.

Cov Qauv thiab Cov Cai rau Neodymium Magnets

American Society of Mechanical Engineers:

Lub Koom Haum American Society of Mechanical Engineers (ASME) muaj cov qauv rau hauv qab-The-Hook Lifting Devices.Standard B30.20 siv rau kev teeb tsa, kev tshuaj xyuas, kev sim, kev saib xyuas thiab kev ua haujlwm ntawm cov khoom nqa nqa, uas suav nrog kev nqa cov hlau nplaum uas tus neeg teb xov tooj tso cov hlau nplaum ntawm lub nra thiab coj cov khoom thauj.ASME tus qauv BTH-1 yog siv ua ke nrog ASME B30.20.

Kev Ntsuam Xyuas Kev Nyab Xeeb thiab Cov Ntsiab Lus Tseem Ceeb:

Hazard Analysis thiab Critical Control Points (HACCP) yog qhov kev lees paub thoob ntiaj teb kev tiv thaiv kev pheej hmoo.Nws tshuaj xyuas kev nyab xeeb ntawm cov zaub mov los ntawm kev lom neeg, tshuaj lom neeg, thiab lub cev muaj kev phom sij los ntawm kev xav tau kev txheeb xyuas thiab kev tswj xyuas cov kev phom sij ntawm qee cov ntsiab lus hauv cov txheej txheem tsim khoom.Nws muaj ntawv pov thawj rau cov cuab yeej siv hauv cov khoom noj khoom haus.HACCP tau txheeb xyuas thiab lees paub qee cov hlau nplaum sib cais siv hauv kev lag luam khoom noj.

United States Department of Agriculture:

Cov cuab yeej sib nqus sib nqus tau raug pom zoo los ntawm Tebchaws Meskas Lub Tsev Haujlwm Saib Xyuas Kev Ua Liaj Ua Teb Kev Ua Liaj Ua Teb Kev Lag Luam Ua Lag Luam raws li kev ua raws li kev siv nrog ob txoj haujlwm ua zaub mov:

- Cov khoom siv mis nyuj tshuaj xyuas qhov program

- Nqaij thiab nqaij qaib cov cuab yeej tshuaj xyuas qhov kev pab cuam

Cov ntawv pov thawj yog nyob ntawm ob tus qauv lossis cov txheej txheem:

- Sanitary Design and Fabrication of Dairy Processing Equipment

- Kev tsim qauv huv huv thiab tsim cov khoom siv nqaij thiab nqaij qaib uas ua tau raws li NSF/ANSI/3-A SSI 14159-1-2014 Kev Tu Kom Huv Huv

Kev txwv tsis pub siv cov khoom tsim kev puas tsuaj:

Kev txwv tsis pub siv cov khoom phom sij (RoHS) cov cai txwv tsis pub siv lead, cadmium, polybrominated biphenyl (PBB), mercury, hexavalent chromium, thiab polybrominated diphenyl ether (PBDE) nplaim retardants hauv cov khoom siv hluav taws xob.Txij li cov hlau nplaum neodymium tuaj yeem ua rau muaj kev phom sij, RoHS tau tsim cov qauv rau lawv tuav thiab siv.

International Civil Aviation Organization:

Cov hlau nplaum tau txiav txim siab ua qhov zoo txaus ntshai rau kev xa khoom sab nraud Continental United States mus rau cov chaw thoob ntiaj teb.Txhua yam khoom ntim, yuav tsum tau xa los ntawm huab cua, yuav tsum muaj lub zog sib nqus ntawm 0.002 Gauss lossis ntau dua ntawm qhov deb ntawm xya feet ntawm ib qho chaw ntawm lub pob.

Federal Aviation Administration:

Cov pob khoom uas muaj hlau nplaum raug xa los ntawm huab cua yuav tsum tau sim kom ua tau raws li cov qauv tsim.Cov pob hlau nplaum yuav tsum ntsuas tsawg dua 0.00525 gauss ntawm 15 ko taw ntawm pob.Cov hlau nplaum muaj zog thiab muaj zog yuav tsum muaj qee yam kev tiv thaiv.Muaj ntau txoj cai thiab yuav tsum tau ua kom tau raws li cov hlau nplaum thauj khoom los ntawm huab cua vim tias muaj kev phom sij rau kev nyab xeeb.

Kev txwv, kev ntsuam xyuas, kev tso cai ntawm cov tshuaj:

Kev Txwv, Kev Ntsuas, thiab Kev Tso Cai ntawm Tshuaj (REACH) yog lub koom haum thoob ntiaj teb uas yog ib feem ntawm European Union.Nws tswj thiab tsim cov qauv rau cov khoom siv phom sij.Nws muaj ntau yam ntaub ntawv uas qhia txog kev siv kom raug, tuav, thiab tsim cov hlau nplaum.Ntau cov ntaub ntawv hais txog kev siv cov hlau nplaum hauv cov khoom siv kho mob thiab cov khoom siv hluav taws xob.

Xaus

- Neodymium (Nd-Fe-B) hlau nplaum, hu ua neo hlau nplaum, yog cov hlau nplaum uas tsis tshua muaj hauv ntiaj teb uas muaj xws li neodymium (Nd), hlau (Fe), boron (B), thiab cov hlau hloov pauv.

- Ob txheej txheem siv los tsim cov hlau nplaum neodymium yog sintering thiab bonding.

- Neodymium hlau nplaum tau dhau los ua cov khoom siv dav tshaj plaws ntawm ntau hom hlau nplaum.

- Lub magnetic teb ntawm neodymium hlau nplaum tshwm sim thaum lub magnetic teb yog siv rau nws thiab lub atomic dipoles dlhos, uas yog lub sib nqus hysteresis voj.

- Neodymium hlau nplaum tuaj yeem tsim nyob rau hauv txhua qhov loj me tab sis khaws lawv qhov pib sib nqus zog.

Post lub sij hawm: Lub Xya hli ntuj-11-2022