Magnetic Coupling yog dab tsi?

Sib Nqus Couplingyog ib hom tshiab ntawm coupling uas txuas cov prime mover thiab lub tshuab ua hauj lwm los ntawm kev sib nqus quab yuam ntawm cov hlau nplaum ruaj khov. Magnetic Coupling tsis xav tau kev sib txuas ncaj qha, tab sis siv kev sib cuam tshuam ntawm lub ntiaj teb tsis tshua muaj cov hlau nplaum ruaj khov, siv cov hlau nplaum kom nkag mus rau qee qhov kev ncua deb thiab cov yam ntxwv ntawm cov khoom siv los xa cov tshuab hluav taws xob.

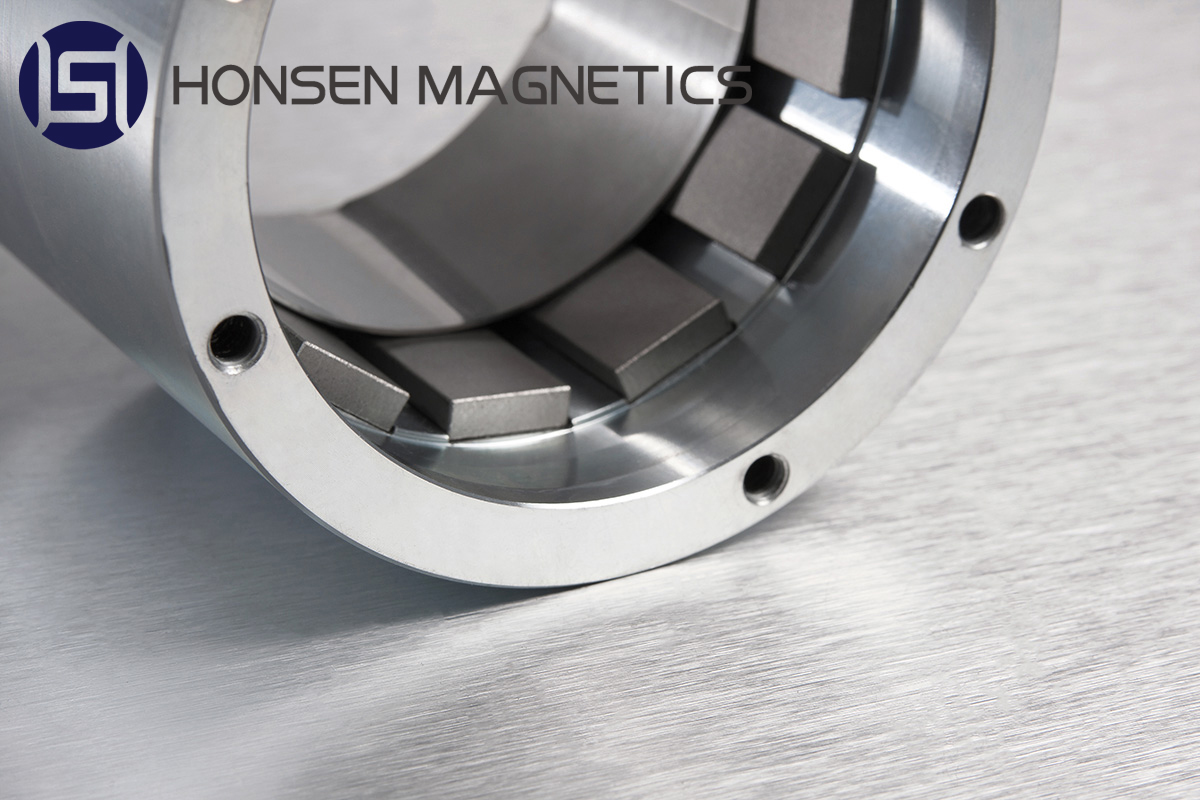

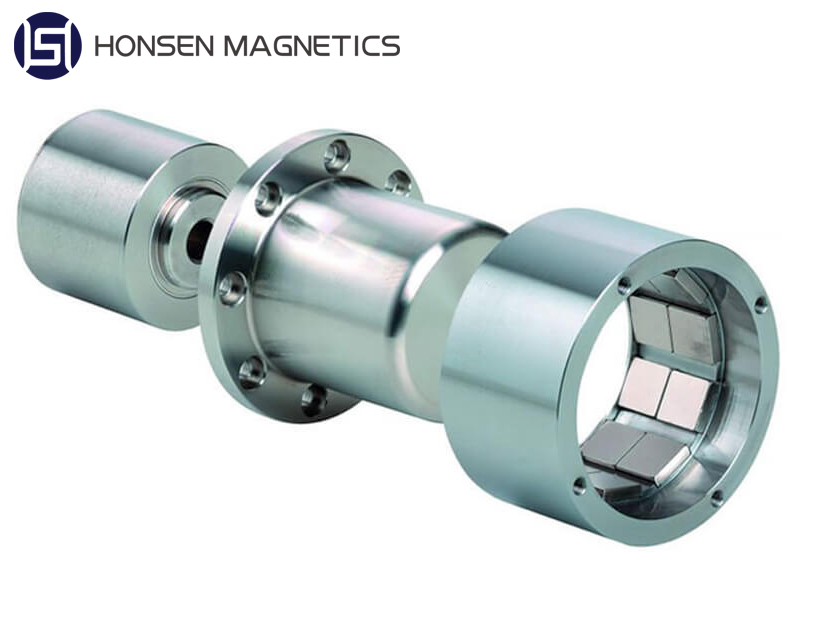

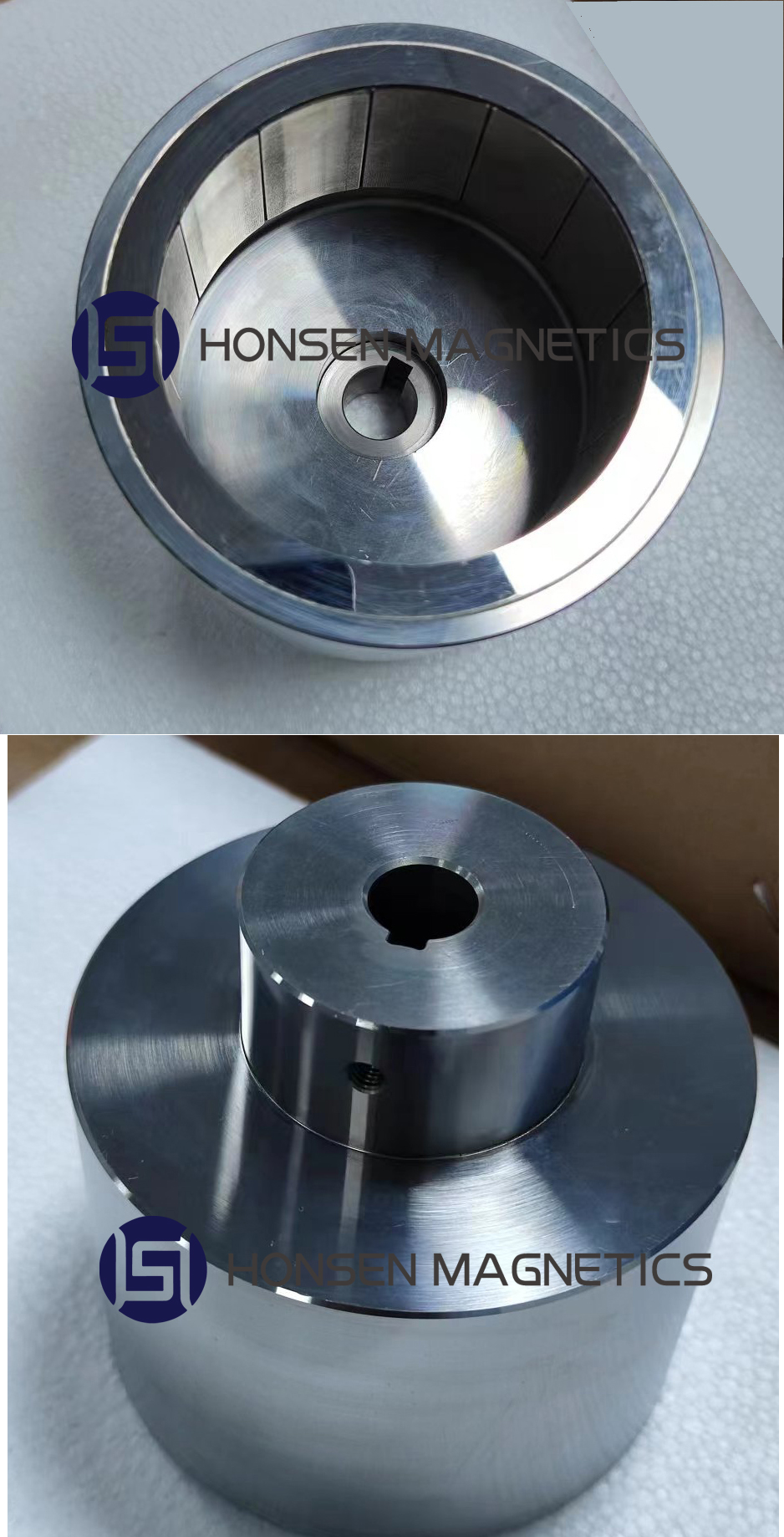

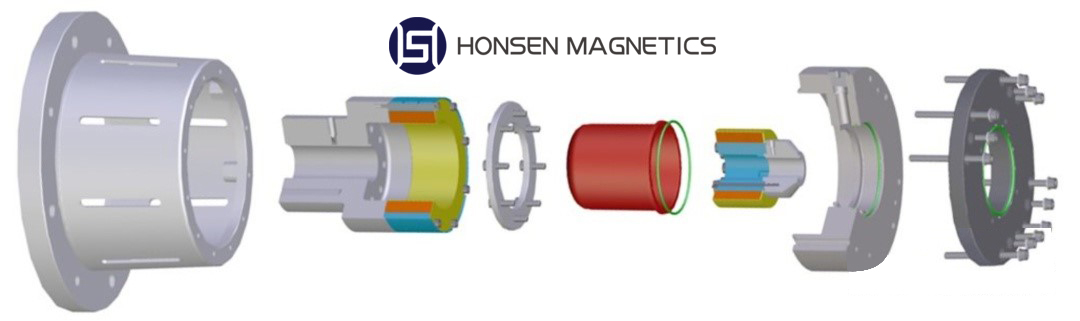

Cov hlau nplaum sib txuas feem ntau muaj lub rotor sab nraud, lub rotor sab hauv, thiab lub sealing tau (lub tes tsho cais). Ob lub rotors yog sib cais los ntawm kev sib cais npog hauv nruab nrab, nrog cov hlau nplaum sab hauv txuas nrog lub zog tsav thiab cov hlau nplaum sab nraud txuas nrog lub zog tivthaiv.

Qhov sib nqus couplings tuaj yeem kho tau. Cov hlau nplaum ruaj khov feem ntau sivSmColos yogNdFeB hlau nplaum, thiab cov qib tshwj xeeb yuav tsum tau txiav txim siab raws li qhov kub thiab txias ua haujlwm, ib puag ncig ua haujlwm, thiab sib txuas torque. Lub plhaub feem ntau yog ua los ntawm stainless hlau (Q235A, 304/316L).

Cov hlau nplaum txuas tuaj yeem siv tau rau ntau hom twj thiab cov khoom sib xyaw xws li cov twj tso kua mis, cov twj tso kua mis, thiab lwm yam. Cov hlau nplaum sib txuas tuaj yeem siv los ua kom tsis muaj cov twj tso kua mis los tiv thaiv kev puas tsuaj los ntawm corrosive kua xov xwm dhau los ntawm cov ntsaws ruaj ruaj. Sib nqus Couplings kuj tuaj yeem siv rau cov khoom siv hluav taws xob submersible, xws li cov twj submersible, nrog rau ntau lub tshuab nqus tsev thiab cov roj sib sib zog nqus dej hiav txwv.

Kev faib tawm ntawm Magnetic Couplings

- Muab faib rau hauv kev sib nqus sib nqus, nws tau muab faib ua kev sib kis sib txuas (planar thiab coaxial), eddy tam sim no kis tau tus mob, thiab hysteresis kis tau tus mob;

- Muab faib ua cov lus tsa suab, kev sib hloov, thiab cov lus sib xyaw ua ke raws li hom kev sib kis;

- Muab faib ua cov qauv sib txawv, nws tuaj yeem muab faib ua cylindrical magnetic couplings thiab tiaj tus disk sib nqus couplings;

- Muab faib ua cov qauv kev ua haujlwm sib txawv, nws tuaj yeem muab faib ua synchronous magnetic coupling thiab asynchronous magnetic coupling.

- Muab faib rau hauv kev teeb tsa ntawm cov hlau nplaum ruaj khov, lawv tau muab faib ua qhov sib txawv dispersed hom thiab sib xyaw rub hom.

Dab tsi yog lub ntsiab technical parameters ntawm Magnetic Coupling?

Thaum xaiv cov hlau nplaum sib nqus, nws yuav tsum ua tib zoo xav txog cov xwm txheej xws li cov xwm txheej tshwj xeeb, lub cev muaj zog thiab kev thauj khoom, thiab cov kev xav tau ntawm kev ua haujlwm, thiab xaiv cov txheej txheem tsim nyog thiab cov txheej txheem teeb tsa.

Sib nqus coupling yog ib qho khoom siv kis tau tus mob uas siv cov magnetic teb torque los xa cov torque, thiab nws cov ntsiab lus tseem ceeb muaj xws li cov hauv qab no:

- Maximum torque: sawv cev rau qhov siab tshaj plaws torque uas sib nqus sib nqus tuaj yeem tso tawm. Qhov kev ntsuas no zoo sib xws rau qhov xwm txheej ntawm daim ntawv thov, thiab feem ntau, nws yog qhov tsim nyog los xaiv qhov tsim nyog tus nqi siab tshaj plaws torque raws li qhov xav tau tiag tiag.

- Ua hauj lwm ceev: sawv cev rau qhov siab tshaj plaws ceev uas sib nqus coupling tuaj yeem tiv taus. Qhov kev ntsuas no cuam tshuam rau ntau yam ntawm kev siv cov hlau nplaum sib nqus, thiab feem ntau, kev ua haujlwm ceev uas tuaj yeem ua tau raws li qhov yuav tsum tau xaiv.

- Poob zog: Hais txog lub zog nqus los ntawm kev sib nqus sib nqus los hloov lub zog sib nqus rau hauv thermal zog lossis lwm yam kev poob. Qhov tsawg dua qhov poob lub zog, qhov ua tau zoo ntawm cov hlau nplaum sib txuas ntau dua, thiab cov khoom siv hluav taws xob tsawg yuav tsum raug xaiv kom ntau li ntau tau.

Dab tsi yog qhov ua tau zoo ntawm Magnetic Couplings?

Magnet Coupling yog ib hom kev sib txuas raws li kev sib txuas ntawm lub zog sib nqus los ntawmCov khoom siv hlau nplaum ruaj khov, uas muaj cov yam ntxwv ua haujlwm hauv qab no:

- Kev sib kis tau zoo: Piv nrog cov khoom sib txuas ib txwm siv, cov khoom sib nqus siv cov khoom siv hlau nplaum ruaj khov ua cov khoom sib nqus, ua rau muaj kev sib kis tau zoo dua, ncav cuag ntau dua 99%.

- High torque ceev: Vim lub siab sib nqus zog khoom ntawm cov khoom siv hlau nplaum tas mus li, sib nqus couplings ntawm tib qhov loj tuaj yeem tiv taus ntau dua torque piv rau cov khoom qub.

- Qhov tseeb torque kis tau tus mob: Cov kis tau tus mob torque ntawm lub sib nqus coupling yog linearly muaj feem xyuam rau cov input ceev, yog li nws muaj peev xwm raug xa mus rau lub torque uas ua tau raws li qhov yuav tsum tau ua nyob rau hauv lub tswv yim ua hauj lwm thiab muaj zog adaptability.

- Muaj zog sib nqus ruaj khov: Cov khoom siv hlau nplaum tas mus li muaj kev ruaj khov thiab sib nqus teb rov qab. Txawm tias nyob rau hauv qhov kub thiab av noo ib puag ncig, yuav tsis muaj qhov sib nqus hloov, yog li nws muaj lub neej ua haujlwm ntev.

- Kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig: Vim yog siv cov hlau nplaum sib nqus hauv cov sib nqus sib nqus, piv rau cov khoom siv hluav taws xob ib txwm muaj, lawv tsis tsim hluav taws xob sib txhuam, kub poob, thiab suab nrov, yog li muaj kev txuag hluav taws xob zoo thiab kev tiv thaiv ib puag ncig.

Vim li cas peb thiaj ua tau Zoo dua

Honsen Sib Nqusspecializes nyob rau hauv ntau lawm thiab manufacturing ntawmsib nqus sib nqusthiab magnetic couplings. Pab pawg tseem ceeb muaj tag nrho ntawm cov neeg tsim hluav taws xob sib nqus hluav taws xob thiab cov kws tsim kho tshuab tsim hluav taws xob. Tom qab xyoo ntawm kev ua lag luam kev koom ua ke, peb tau tsim ib pab neeg paub tab: los ntawm kev tsim, thiab kev coj mus kuaj rau batch xa khoom, peb muaj cov cuab yeej siv thiab cov khoom siv uas tuaj yeem tiv nrog ntau lawm, qee qhov tsim thiab tsim los ntawm peb tus kheej, Peb tau cob qhia ib pab pawg. ntawm cov neeg ua haujlwm paub txog kev tsim khoom.

Peb tsis tsuas yog muab ONE-STOP-SERVICE ntawm tus qauv tsim qauv batch xaj khoom xa tuaj tab sis tseem siv zog ua kom sib xws hauv cov khoom lag luam batch. Peb tsom mus txuas ntxiv txhim kho thiab txo kev cuam tshuam tib neeg kom ntau li ntau tau.

Peb qhov zoo hauv kev tsim Magnet Couplings:

- Paub txog ntau hom hlau nplaum, muaj peev xwm xam thiab optimize magnetic circuits. Peb tuaj yeem xam qhov sib nqus Circuit Court quantitatively. Piv txwv li, thaum tus neeg siv khoom qhia txog lub zog ntawm cov hlau nplaum txuas mus tas li, peb tuaj yeem muab cov kev daws teeb meem zoo tshaj plaws thiab tus nqi qis tshaj raws li cov txiaj ntsig suav.

- Kev paub txog Mechanical engineers, mechanical zog, dimensional tolerances, thiab lwm yam ntawmsib nqus sib nqustau tsim thiab tshuaj xyuas los ntawm lawv. Lawv kuj tseem yuav tsim cov phiaj xwm tsim nyog tshaj plaws raws li cov peev txheej ntawm cov khoom siv machining.

- Ua raws li cov khoom sib xws. Muaj ntau hom kev sib nqus ntawm cov khoom sib nqus thiab cov txheej txheem nyuaj, xws li cov txheej txheem gluing. Kev tuav gluing tuaj yeem sib txawv ntawm ib tus neeg mus rau ib tus neeg, thiab cov kua nplaum tsis tuaj yeem tswj tau. Lub tshuab tsis siv neeg xa khoom ntawm lub khw tsis tuaj yeem hloov kho rau peb cov khoom. Peb tau tsim thiab tsim lub tshuab xa tawm rau kev tswj tsis siv neeg kom tshem tawm tib neeg yam.

- Cov neeg ua haujlwm txawj ntse thiab kev tsim kho tshiab tas li! Kev sib dhos ntawm cov hlau nplaum sib nqus thiab cov sib nqus sib nqus yuav tsum muaj cov neeg ua haujlwm sib dhos. Peb tau tsim thiab tsim ntau yam khoom tshwj xeeb thiab zoo heev thiab cov cuab yeej siv los txo kev siv zog, txhim kho kev ua haujlwm, thiab ua kom cov khoom sib xws.

Peb Cov Chaw

Yuav ua li cas peb ua tiav nws

Mloog cov neeg siv khoom xav tau

Txhawm rau kom nkag siab tag nrho cov neeg siv khoom lub hom phiaj, peb yuav coj mus rau hauv tus account tsis yog tsuas yog cov ntsuas kev ua haujlwm tseem ceeb ntawm kev sib nqus sib nqus, tab sis kuj tseem muaj xws li kev ua haujlwm ib puag ncig, kev siv, thiab kev thauj mus los ntawm cov khoom. Los ntawm kev tau txais kev nkag siab zoo ntawm cov khoom no, peb tuaj yeem npaj tau zoo rau theem tom ntej ntawm kev tsim qauv qauv. Qhov kev qhia dav dav no ua kom ntseeg tau tias peb cov qauv tsim ua kom zoo nrog cov neeg siv khoom xav tau thiab lav kev ua haujlwm zoo hauv lub ntiaj teb tiag tiag.

Kev Tsim Qauv Qauv

Pab hauv kev suav thiab tsim cov khoom sib nqus raws li cov neeg siv khoom xav tau. Kev txiav txim siab ua ntej ntawm kev ua thiab kev sib dhos ua ke, thiab raws li peb cov kev paub dhau los thiab cov txiaj ntsig ntawm kev suav, tawm tswv yim kev txhim kho rau cov neeg siv khoom tsim tsis zoo. Thaum kawg, ncav cuag qhov kev pom zoo nrog tus neeg siv khoom thiab kos npe rau daim ntawv xaj xaj.

Ua ntej, raws li peb cov kev paub dhau los thiab CAE-pab suav, tau txais cov qauv zoo. Cov ntsiab lus tseem ceeb ntawm cov qauv yog tias cov hlau nplaum yuav tsum raug txo kom tsawg thiab cov duab ntawm cov hlau nplaum yuav tsum yooj yim rau tshuab. Rau lub hauv paus no, engineers comprehensively xav txog tus qauv qauv kom nws yooj yim rau txheej txheem thiab sib sau ua ke. Npaj peb cov kev xav thiab sib tham nrog cov neeg siv khoom, thiab thaum kawg kos npe rau cov qauv txiav txim.

Tsim cov txheej txheem thiab cov qauv

Tsim cov txheej txheem kom ntxaws thiab nce cov ntsiab lus saib xyuas zoo. Cov khoom tawg daim duab ntawm cov khoom siv hlau nplaum tau pib ntau lawm.

Tsim cov khoom siv: 1. Xyuas kom cov duab, txoj hauj lwm, thiab qhov ntev ntawm cov khoom; 2. Siv los ntsuas cov cuab yeej los xyuas kom zoo.

Qhov no yog ib qho piv txwv ntawm peb qhov chaw kuaj xyuas tshwj xeeb. Tom qab kos npe rau cov qauv kev txiav txim, raws li kev ua thiab cov yam ntxwv ntawm kev sib dhos, peb yuav tsum tsim cov txheej txheem kom ntxaws thiab ua kom muaj kev soj ntsuam zoo hauv cov txheej txheem tseem ceeb. Tib lub sijhawm, peb tsim cov cuab yeej cuab tam. Nyob rau theem no, cov cuab yeej siv los xyuas kom meej qhov geometric thiab qhov ntev ntev ntawm cov khoom thiab tag nrho cov khoom, thiab rau kev ntsuas ntsuas kom ntseeg tau tias peb cov khoom tuaj yeem kuaj xyuas sai thiab zoo hauv cov khoom tom ntej.

Kev tswj ntau lawm

Tom qab tau txais kev txiav txim ntau, npaj cov neeg ua haujlwm ua haujlwm, npaj cov chaw ua haujlwm thiab cov txheej txheem tsim nyog, thiab yog tias tsim nyog, tsim cov cuab yeej tshwj xeeb rau kev ua haujlwm kom txo qis kev siv zog thiab ua kom muaj kev sib luag hauv kev tsim khoom.

Magnet dismantling khoom

Cov hlau nplaum txuas mus tas li, cov hlau nplaum lub cev muaj zog, thiab qee qhov sib nqus sib nqus yuav tsum tau cov hlau nplaum kom muaj hlau nplaum ua ntej sib dhos. Los ntawm txhais tes disassembly ntawm cov hlau nplaum yog qhov tsis muaj txiaj ntsig, thiab qhov tseem ceeb tshaj plaws yog tias nws yog qhov mob heev kom tshem tawm cov hlau nplaum nrog koj cov ntiv tes ntev. Yog li ntawd, peb tau tsim thiab tsim cov cuab yeej me me no los daws cov neeg ua haujlwm mob thiab txhim kho kev ua haujlwm.

Tsis siv neeg gluing khoom

Ntau cov hlau nplaum sib txuas thiab cov khoom siv yuav tsum tau siv cov kua nplaum los txuas cov hlau nplaum muaj zog thiab lwm yam khoom ua ke. Tsis zoo li phau ntawv gluing, cov kua nplaum tsis tuaj yeem tswj tau. Peb tau tsim thiab tsim cov khoom siv gluing tsis siv neeg tshwj xeeb rau peb cov khoom, uas muaj txiaj ntsig zoo thiab muaj txiaj ntsig zoo piv rau cov khoom muag hauv khw.

Tsis siv neeg laser vuam

Ntau yam ntawm peb cov khoom yuav tsum tau laser vuam ntawm workpieces rau sealing lub hom phiaj (qee yam sib nqus Cheebtsam yuav tsum tau cov hlau nplaum yuav tsum tau kaw tag nrho). Nyob rau hauv qhov tseeb vuam, lub workpieces muaj tolerances thiab muaj thermal deformation thaum vuam; Nws tsis yog qhov tsim nyog rau manually weld ntau qhov kev txiav txim. Peb tau tsim thiab tsim ntau yam khoom tshwj xeeb los pab cov neeg pib sai sai pib.

Peb muaj kev paub dhau los hauv kev tswj hwm ntau lawm, thiab peb yuav tsum ua tiav kev tswj kom muaj nuj nqis hauv txhua qhov txheej txheem los xyuas kom meej qhov sib xws hauv txhua pawg ntawm cov khoom.

PACKING & DELIVERY

Q&A

Q: Puas muaj cov duab kos?

A: Peb tau optimized thiab tsim cov series qhov ntev ntawm lub coupling, thiab cov neeg muas zaub tuaj yeem hloov kho raws li qhov no. Thiab peb kuj zoo siab tos txais peb cov neeg siv khoom rau txhua qhov haujlwm customized.

Q: Tus qauv, nqe, thiab lub sijhawm ua haujlwm yog dab tsi?

A: Thaum pib ntawm qhov sib nqus coupling project, kuaj cov qauv ib txwm xav tau, yog li peb lees txais cov qauv txiav txim. Txawm li cas los xij, txhawm rau tshuaj xyuas cov neeg siv khoom nrog cov phiaj xwm batch, peb yuav them tus nqi qis dua. Peb yuav them tus nqi coj mus kuaj txij li 3000 txog 8000 yuan rau lub zog ntawm 0.1 Nm txog 80 Nm, thiab lub sijhawm xa khoom feem ntau yog 35 txog 40 hnub.

Q: Yuav ua li cas txog MOQ thiab tus nqi?

A: Raws li kev ua haujlwm nyuaj, ua cov phiaj xwm txiav txim thiab cov lus hais.

Q: Koj puas muaj cov khoom muag?

A: Sib nqus couplings feem ntau customized. Piv txwv li, yog tias cov neeg siv khoom xav tau qhov sib txawv ntawm qhov sib txawv, peb yuav tsum tau rov ua haujlwm dua, yog li peb tsis tuaj yeem npaj cov khoom tiav. Tag nrho customized ntau lawm, tsis muaj cov khoom muag.

Q: Puas yuav sib nqus couplings poob kev sib nqus?

A: Sib nqus couplings siv cov hlau nplaum ruaj khov kom xa cov torque yam tsis muaj qhov khoob. Thaum cov hlau nplaum ruaj khov demagnetizes lossis poob excitation, cov hlau nplaum sib txuas ua haujlwm tsis zoo. Cov txheej txheem demagnetization tseem ceeb ntawm cov hlau nplaum tas mus li muaj xws li qhov kub thiab txias, kev co, rov qab sib nqus teb, thiab lwm yam. Yog li ntawd, peb cov hlau nplaum sib nqus yuav tsum ua haujlwm nyob rau hauv ib qho synchronous lub xeev ntawm lub puab thiab sab nrauv rotors. Thaum lub load loj dhau lawm, lub rotor sab nraud rov ua haujlwm rov qab magnetic teb ntawm lub rotor sab hauv, uas yog yooj yim demagnetized, ua rau torque txo los yog ua tsis tiav.

Q: Kuv yuav tsum xyuam xim rau dab tsi thaum txhim kho cov hlau nplaum sib txuas?

A: Lub sib nqus coupling yog ib qho tsis sib cuag, nrog rau qhov sib txawv ntawm lub rotor sab nrauv thiab lub tes tsho cais, nrog rau ntawm lub tes tsho cais thiab lub rotor sab hauv, zoo heev txo qhov nyuaj ntawm kev teeb tsa. Txawm li cas los xij, cov phab ntsa tuab ntawm lub tes tsho cais yog nyias nyias, thiab yog tias nws sib tsoo nrog lwm cov khoom lossis cov khoom hnyav thaum lub sijhawm ua haujlwm, nws yuav ua rau lub tes tsho cais thiab tsis ua haujlwm raws li lub foob. Yog li ntawd, nws yog ib qho tsim nyog los xyuas kom meej ib co coaxiality raws li qhov sib txawv clearances.

Q: Yuav xaiv tus qauv li cas?

A: Ua ntej, txiav txim siab lub zog ntawm qhov sib txuas me me raws li qhov ntsuas lub zog thiab ntsuas qhov ceev ntawm lub cev muaj zog. Cov mis laij lej ntxhib yog coupling torque (Nm) = 10000 * lub cev muaj zog (kW) / lub cev muaj zog (RPM); Qhov thib ob, nws yog ib qho tsim nyog kom nkag siab txog qhov ua haujlwm kub, ua haujlwm siab, thiab nruab nrab los tiv thaiv corrosion. Peb cov hlau nplaum sib txuas yuav tsum muaj qhov ceev tsawg dua 3000RPM thiab ua haujlwm siab tsawg dua 2MPa.

Q: Yuav ua li cas thiaj ua tau cov hlau nplaum ruaj khov?

A: Magnet Couplings kuj muaj nyob rau hauv ntau hom qauv. Peb cov hlau nplaum txuas mus tas li siv lub hauv paus ntsiab lus ntawm cov hlau nplaum muaj zog sib txuas rau qhov tsis sib cuag. Tsim los ntawm sab hauv thiab sab nrauv rotors, sib sau ua ke nrog cov hlau nplaum muaj zog. Lub cev muaj zog tsav lub rotor sab nraud kom tig thaum hloov lub zog kinetic mus rau sab hauv rotor los ntawm cov hlau nplaum ntawm cov rotor sab hauv thiab sab nrauv, ua rau lub rotor sab hauv tig synchronously. Hom kev sib nqus sib nqus no ua tiav qhov kev sib khi zoo li qub vim tsis muaj kev sib txuas nyuaj ntawm cov khoom sib txuas sab hauv thiab sab nraud thiab tau siv dav hauv cov tshuab xa mus rau corrosive, tshuaj lom, thiab kuab paug los yog gases.