Qhov loj tshaj plaws daim ntawv thov teb ntawmrare ntiaj teb mus tas li hlau nplaumyog cov hlau nplaum ruaj khov motors, feem ntau hu ua motors.

Motors nyob rau hauv kev txiav txim siab dav muaj xws li cov motors uas hloov hluav taws xob rau hauv lub tshuab hluav taws xob thiab cov tshuab hluav taws xob uas hloov tshuab hluav taws xob rau hauv hluav taws xob. Ob hom motors cia siab rau lub hauv paus ntsiab lus ntawm electromagnetic induction los yog electromagnetic quab yuam raws li lawv cov hauv paus ntsiab lus. Cov huab cua-gap magnetic teb yog qhov yuav tsum tau ua ua ntej rau kev ua haujlwm ntawm lub cev muaj zog. Lub cev muaj zog uas tsim kom muaj huab cua sib nqus sib nqus los ntawm kev ua kom muaj zog yog hu ua lub cev muaj zog induction, thaum lub cev muaj zog uas tsim cov cua sib nqus sib nqus los ntawm cov hlau nplaum tas mus li hu ua lub tshuab hlau nplaum ruaj khov.

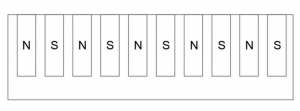

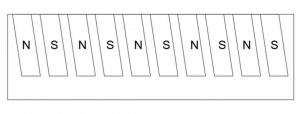

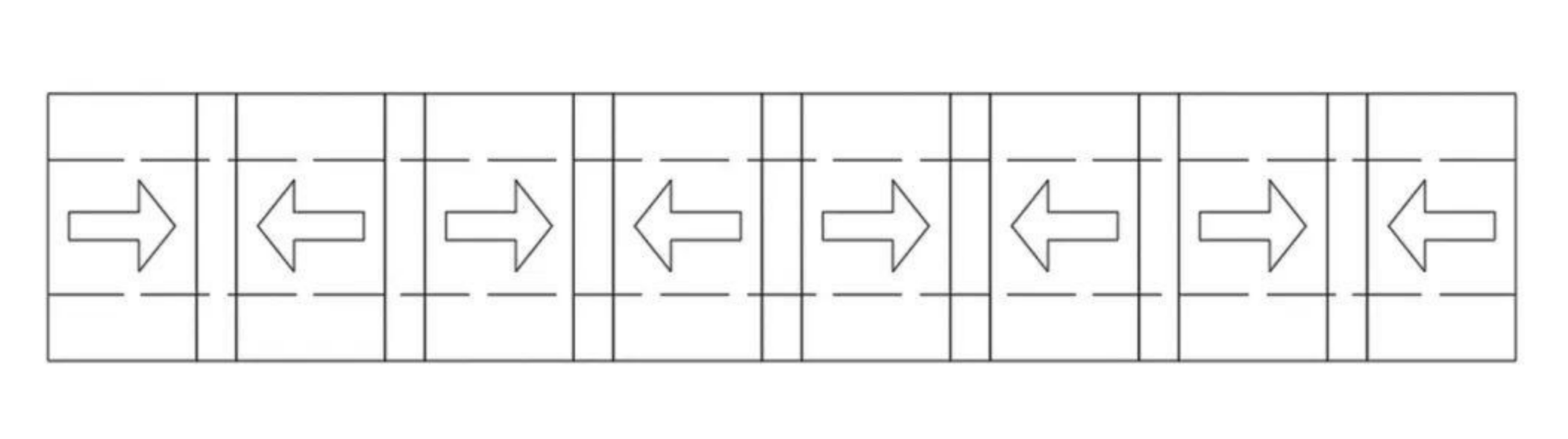

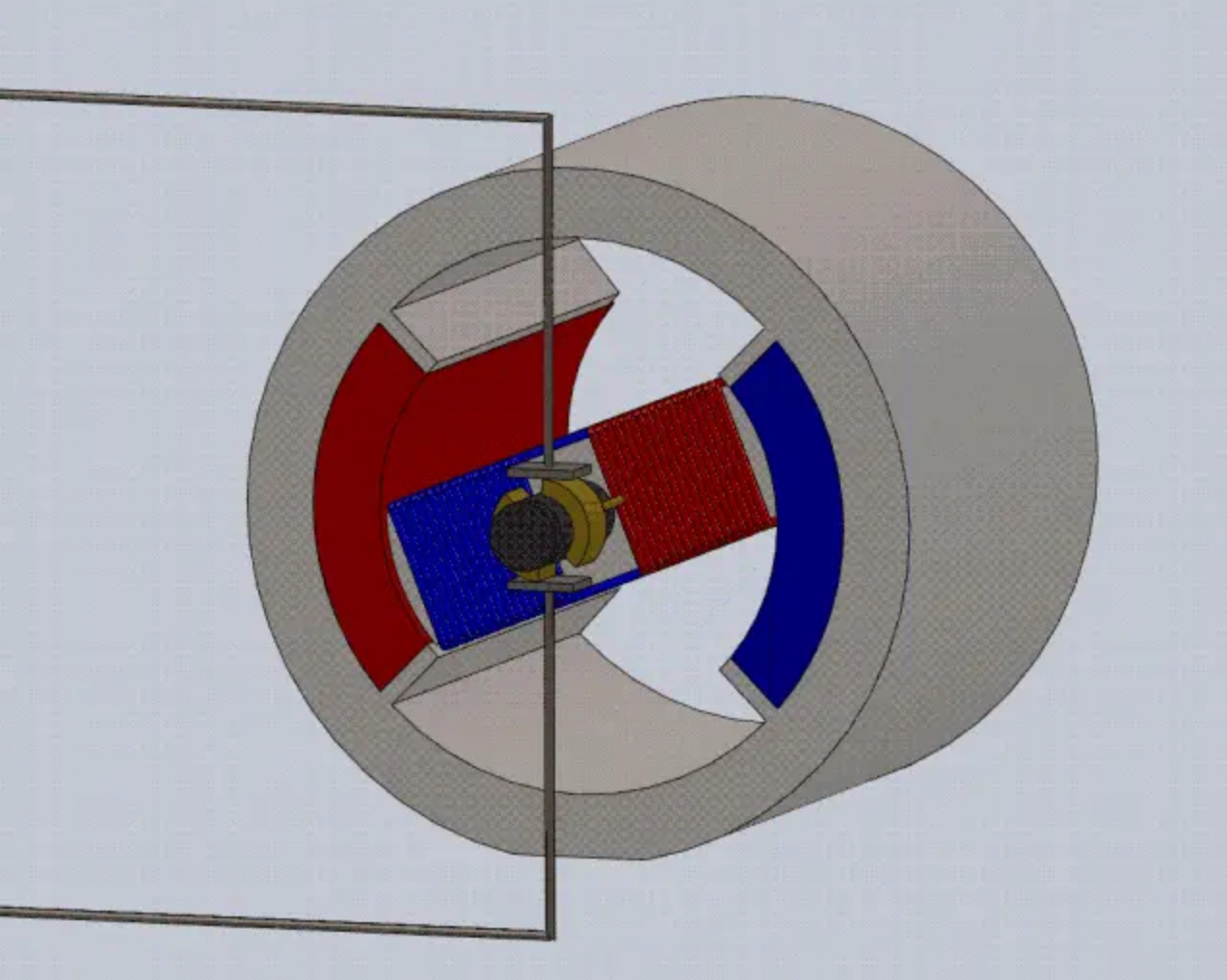

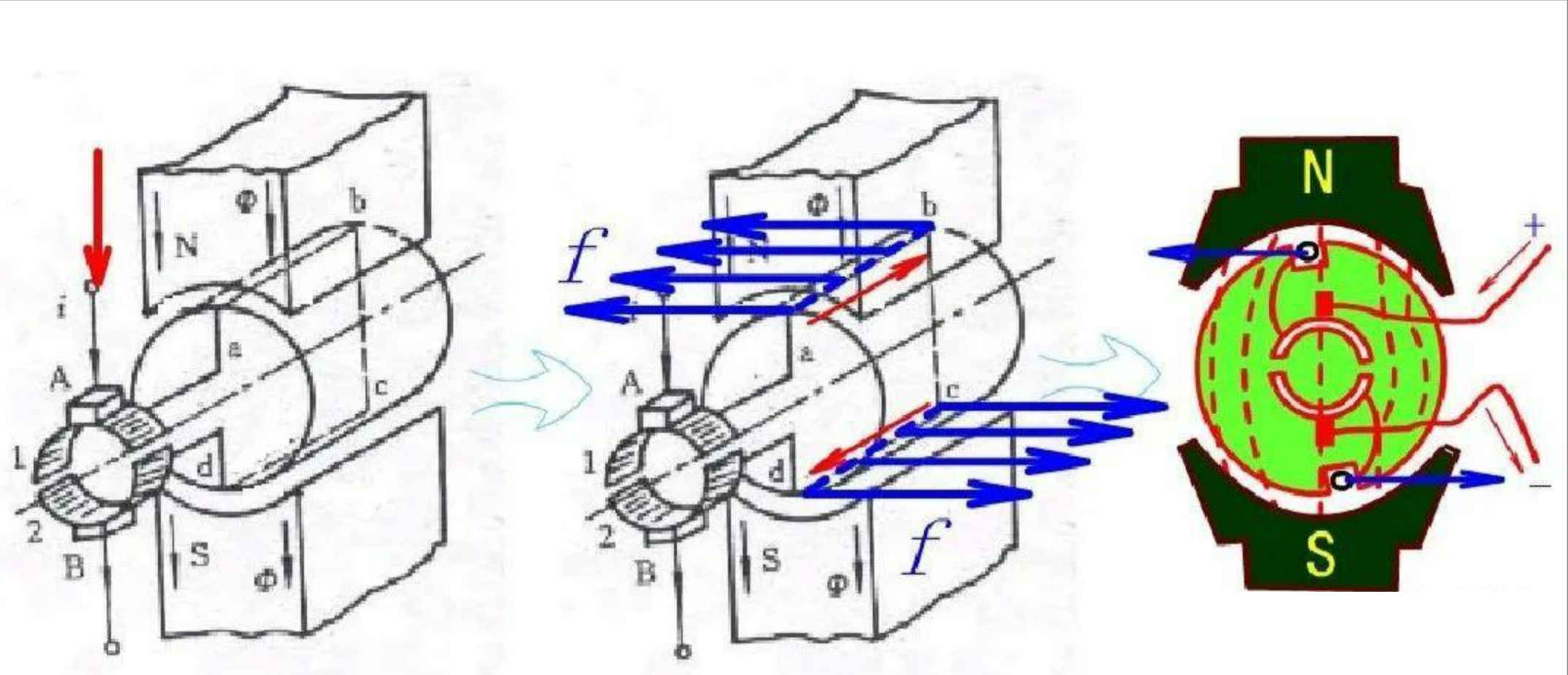

Nyob rau hauv ib lub cev muaj zog hlau nplaum ruaj khov, cov cua sib nqus sib nqus yog tsim los ntawm cov hlau nplaum tas mus li yam tsis tas yuav muaj hluav taws xob ntxiv lossis ntxiv windings. Yog li ntawd, qhov zoo tshaj plaws ntawm cov hlau nplaum ruaj khov motors tshaj induction motors yog kev ua haujlwm siab, txuag hluav taws xob, compact loj, thiab cov qauv yooj yim. Yog li ntawd, cov hlau nplaum ruaj khov motors tau siv dav hauv ntau yam me me thiab micro motors. Daim duab hauv qab no qhia txog kev ua haujlwm yooj yim ntawm cov hlau nplaum ruaj khov DC lub cev muaj zog. Ob lub hlau nplaum ruaj khov tsim ib qho chaw sib nqus nyob hauv nruab nrab ntawm lub kauj. Thaum lub kauj yog energized, nws muaj ib tug electromagnetic quab yuam (raws li txoj cai sab laug) thiab tig. Lub rotating ib feem nyob rau hauv ib tug hluav taws xob lub cev muaj zog yog hu ua lub rotor, thaum lub sij hawm nyob twj ywm ib feem yog hu ua stator. Raws li tuaj yeem pom los ntawm daim duab, cov hlau nplaum ruaj khov yog nyob rau hauv stator, thaum lub coils yog nyob rau hauv lub rotor.

Rau cov motors teb, thaum cov hlau nplaum tas mus li yog lub stator, nws feem ntau sib sau ua ke hauv kev teeb tsa # 2, qhov twg cov hlau nplaum txuas nrog lub cev muaj zog. Thaum cov hlau nplaum ruaj khov yog lub rotor, nws feem ntau sib sau ua ke hauv kev teeb tsa # 1, nrog cov hlau nplaum affixed rau rotor core. Xwb, configurations #3, #4, #5, thiab #6 koom nrog embedding cov hlau nplaum rau hauv lub rotor core, raws li qhia nyob rau hauv daim duab.

Rau linear motors, cov hlau nplaum ruaj khov yog feem ntau nyob rau hauv daim ntawv ntawm squares thiab parallelograms. Tsis tas li ntawd, cylindrical linear motors siv axially magnetized annular hlau nplaum.

Cov hlau nplaum nyob rau hauv Permanent Magnet Tsav muaj cov yam ntxwv hauv qab no:

1. Cov duab tsis yooj yim heev (tshwj tsis yog qee lub tshuab micro, xws li VCM motors), feem ntau yog cov duab plaub, trapezoidal, kiv cua zoo li, thiab cov ntawv ci ci. Tshwj xeeb, nyob rau hauv qhov chaw ntawm kev txo cov nqi tsim lub cev muaj zog, ntau tus yuav siv cov hlau nplaum embedded square.

2. Magnetization yog qhov yooj yim, feem ntau yog ib tus ncej hlau nplaum, thiab tom qab sib dhos, nws tsim ib lub voj voog sib nqus sib nqus. Yog hais tias nws yog ib lub nplhaib ua tiav, xws li cov nplaum neodymium hlau boron nplhaib los yog lub nplhaib kub nias, nws feem ntau yog siv ntau tus ncej hluav taws xob magnetization.

3. Lub hauv paus ntawm cov kev xav tau tshwj xeeb yog nyob rau hauv qhov kub thiab txias stability, sib nqus flux sib xws, thiab hloov tau. Nto-mounted rotor hlau nplaum xav tau cov khoom nplaum zoo, cov kab hlau nplaum lub cev muaj zog muaj kev xav tau ntau dua rau cov tshuaj ntsev, cua tshuab hluav taws xob cov hlau nplaum muaj qhov xav tau ntau dua rau cov tshuaj ntsev, thiab tsav lub cev muaj zog hlau nplaum yuav tsum muaj kev ruaj ntseg zoo heev.

4. High, nruab nrab, thiab qib qis cov khoom siv hluav taws xob sib nqus tau siv tag nrho, tab sis kev sib koom tes feem ntau yog nyob rau nruab nrab mus rau qib siab. Tam sim no, cov qib siv hlau nplaum feem ntau siv rau lub tsheb fais fab tsav tsheb yog cov khoom siv hluav taws xob zoo sib nqus thiab kev sib zog siab, xws li 45UH, 48UH, 50UH, 42EH, 45EH, thiab lwm yam, thiab cov tshuab mature diffusion yog qhov tseem ceeb.

5. Cov segmented nplaum laminated hlau nplaum tau dav siv nyob rau hauv high-temperature motor fields. Lub hom phiaj yog txhawm rau txhim kho segmentation rwb thaiv tsev ntawm cov hlau nplaum thiab txo cov eddy tam sim no poob thaum lub sijhawm ua haujlwm lub cev muaj zog, thiab qee cov hlau nplaum yuav ntxiv epoxy txheej rau saum npoo kom lawv cov rwb thaiv tsev.

Cov khoom tseem ceeb rau cov hlau nplaum lub cev muaj zog:

1. High-temperature stability: Qee cov neeg siv khoom yuav tsum ntsuas qhov qhib-circuit magnetic decay, thaum lwm tus yuav tsum ntsuas ib nrab-qhib-circuit magnetic decay. Thaum lub sijhawm ua haujlwm ntawm lub cev muaj zog, cov hlau nplaum yuav tsum tiv taus qhov kub thiab txias thiab hloov pauv cov hlau nplaum rov qab. Yog li ntawd, kev ntsuam xyuas thiab kev soj ntsuam ntawm cov khoom tiav lawm magnetic decay thiab high-temperature demagnetization curves ntawm lub hauv paus khoom yog tsim nyog.

2. Sib nqus flux sib xws: Raws li lub hauv paus ntawm magnetic teb rau lub cev muaj zog rotors los yog stators, yog tias muaj inconsistencies nyob rau hauv sib nqus flux, nws yuav ua rau lub cev muaj zog vibration, thiab txo hwj chim, thiab muaj feem xyuam rau tag nrho cov hauj lwm ntawm lub cev muaj zog. Yog li, cov hlau nplaum lub cev muaj zog feem ntau muaj qhov yuav tsum tau ua kom sib nqus flux sib xws, qee qhov hauv 5%, qee qhov hauv 3%, lossis txawm nyob hauv 2%. Cov yam ntxwv uas cuam tshuam qhov sib nqus flux sib xws, xws li qhov sib xws ntawm cov hlau nplaum seem, kev kam rau siab, thiab chamfer txheej, yuav tsum tau txiav txim siab.

3. Adaptability: Nto-mounted hlau nplaum yog feem ntau nyob rau hauv cov pobzeb zoo li. Cov qauv kev ntsuas ob sab rau cov kaum sab xis thiab radii yuav muaj qhov yuam kev loj lossis nyuaj rau kev sim. Hauv qhov no, kev hloov pauv yuav tsum tau xav txog. Rau cov hlau nplaum zoo sib xws, cov khoob khoob khoob yuav tsum tau tswj. Rau cov hlau nplaum nrog dovetail slots, sib dhos nruj yuav tsum tau xav txog. Nws yog qhov zoo tshaj plaws los ua kev cai-zoo li tus fixtures raws li tus neeg siv los ua ke txoj kev los ntsuam xyuas qhov adaptability ntawm cov hlau nplaum.

Post lub sij hawm: Aug-24-2023