Magnet yog dab tsi?

Cov hlau nplaum yog cov khoom siv uas siv zog rau nws yam tsis muaj kev sib cuag nrog lwm cov ntaub ntawv. Lub zog no hu ua magnetism. Sib nqus quab yuam tuaj yeem nyiam lossis tawm tsam. Feem ntau cov ntaub ntawv paub muaj qee lub zog sib nqus, tab sis lub zog sib nqus hauv cov ntaub ntawv no tsawg heev. Rau qee cov ntaub ntawv, lub zog sib nqus yog loj heev, yog li cov ntaub ntawv no hu ua hlau nplaum. Lub ntiaj teb nws tus kheej kuj yog cov hlau nplaum loj.

Muaj ob lub ntsiab lus ntawm tag nrho cov hlau nplaum uas lub zog sib nqus loj tshaj. Lawv hu ua tus ncej. Ntawm ib lub voj voos hlau nplaum, cov ncej yog ncaj qha hla ib leeg. Lawv hu ua North Ncej lossis sab qaum teb nrhiav ncej, thiab Sab Qab Teb Ncej lossis sab qab teb nrhiav.

Ib qho hlau nplaum tuaj yeem ua tau yooj yim los ntawm kev siv cov hlau nplaum uas twb muaj lawm thiab rub ib daim hlau nrog nws. Cov khoom siv hlau no yuav tsum tau rubbed tsis tu ncua nyob rau hauv ib qho kev taw qhia. Qhov no ua rau cov hluav taws xob hauv cov hlau ntawd pib tig mus rau tib qho kev taw qhia. Hluav taws xob tam sim no kuj muaj peev xwm tsim cov hlau nplaum. Txij li thaum hluav taws xob yog cov dej ntws ntawm cov hluav taws xob, thaum cov hluav taws xob hluav taws xob txav mus rau hauv cov hlau lawv nqa nrog lawv tib yam li cov hluav taws xob tig ncig lub atomic nucleus. Qhov no yog hu ua electromagnet.

Vim txoj kev lawv cov electrons raug teeb tsa, cov hlau nickel, cobalt, hlau, thiab hlau ua cov hlau nplaum zoo heev. Cov hlau no tuaj yeem nyob hlau nplaum mus ib txhis thaum lawv dhau los ua hlau nplaum. Yog li nqa lub npe nyuaj hlau nplaum. Txawm li cas los xij cov hlau thiab lwm tus tuaj yeem coj tus cwj pwm zoo li cov hlau nplaum ib ntus yog tias lawv tau raug los yog los ze rau cov hlau nplaum nyuaj. Tom qab ntawd lawv nqa lub npe mos hlau nplaum.

Yuav ua li cas Magnetism ua haujlwm

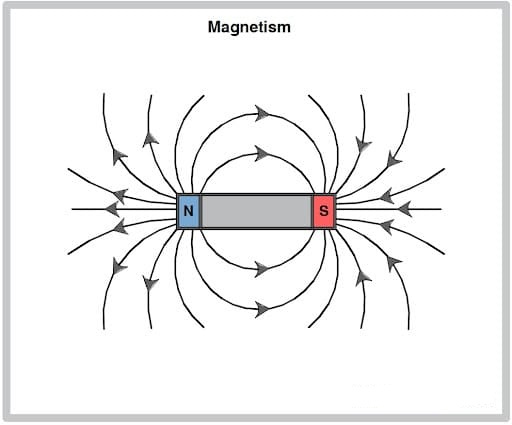

Magnetism tshwm sim thaum cov khoom me me hu ua electrons txav hauv qee txoj kev. Tag nrho cov teeb meem yog tsim los ntawm units hu ua atoms, uas nyob rau hauv lem yog tsim ntawm electrons thiab lwm yam hais, uas yog neutrons thiab protons. Cov electrons no zoo li tig ib ncig ntawm lub nucleus, uas muaj lwm yam hais saum toj no. Lub zog sib nqus me me yog tshwm sim los ntawm kev sib hloov ntawm cov electrons. Qee zaum, ntau cov khoom siv hluav taws xob hauv cov khoom tig mus rau hauv ib qho kev taw qhia. Qhov tshwm sim ntawm tag nrho cov me me sib nqus zog los ntawm electrons yog cov hlau nplaum loj.

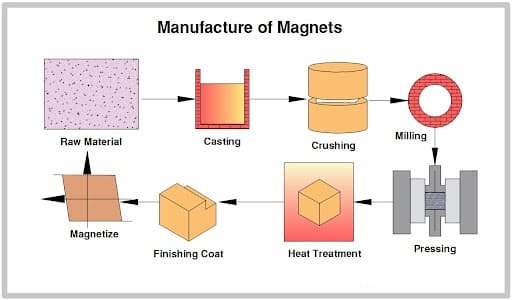

Npaj cov hmoov

Cov nqi tsim nyog ntawm cov hlau, boron, thiab neodymium yog rhuab kom yaj nyob rau hauv lub tshuab nqus tsev los yog nyob rau hauv ib tug induction melting rauv siv inert gas. Kev siv lub tshuab nqus tsev yog los tiv thaiv cov tshuaj lom neeg ntawm cov khoom siv melting thiab cua. Thaum lub molten alloy tau txias, nws yog tawg thiab crushed ua me me hlau strips. Tom qab ntawd, cov khoom me me yog pulverized thiab crushed rau hauv cov hmoov zoo uas muaj li ntawm 3 mus rau 7 microns inch. Cov hmoov tsim tawm tshiab yog qhov muaj zog heev thiab muaj peev xwm ua rau muaj hluav taws kub hnyiab hauv huab cua thiab yuav tsum tau ceev kom tsis txhob raug oxygen.

Isostatic Compaction

Cov txheej txheem ntawm isostatic compaction kuj hu ua nias. Cov hmoov hlau yog muab thiab muab tso rau hauv pwm. Cov pwm no kuj hu ua tuag. Txhawm rau kom cov khoom siv hmoov sib xyaw ua ke nrog cov hmoov sib nqus tau siv zog, thiab thaum lub sijhawm siv lub zog sib nqus, hydraulic rams yog siv los txhuam nws tag nrho rau hauv 0.125 ntiv tes (0.32 cm) ntawm nws cov phiaj xwm. tuab. Kev kub siab feem ntau yog siv los ntawm 10,000 psi mus rau 15,000 psi (70 MPa rau 100 MPa). Lwm cov qauv tsim thiab cov duab yog tsim los ntawm kev muab cov khoom tso rau hauv lub thawv airtight evacuated ua ntej nias rau hauv cov duab uas xav tau los ntawm cov pa roj.

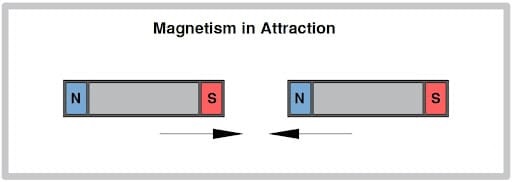

Feem ntau ntawm cov khoom siv piv txwv, ntoo, dej, thiab huab cua muaj cov khoom sib nqus uas tsis muaj zog heev. Cov hlau nplaum nyiam cov khoom uas muaj cov hlau qub heev. Lawv kuj nyiam lossis tawm tsam lwm cov hlau nplaum nyuaj thaum lawv coj los ze zog. Qhov no tshwm sim yog vim hais tias txhua lub hlau nplaum muaj ob tug opposite ncej. Cov ncej sab qab teb nyiam cov ncej qaum teb ntawm lwm cov hlau nplaum, tab sis lawv tawm tsam lwm cov ncej sab qab teb thiab rov ua dua.

Manufacturing Magnets

Txoj kev siv ntau tshaj plaws hauv kev tsim cov hlau nplaum yog hu ua hmoov metallurgy. Txij li cov hlau nplaum muaj cov khoom sib txawv, cov txheej txheem ntawm kev tsim lawv kuj txawv thiab tshwj xeeb ntawm lawv tus kheej. Piv txwv li, electromagnets yog tsim los siv cov txheej txheem hlau casting, thaum lub sij hawm hloov pauv mus tas li cov hlau nplaum yog tsim los ntawm cov txheej txheem uas muaj cov yas extrusion uas cov khoom siv raw sib xyaw ua ntej yuav raug yuam los ntawm kev qhib nyob rau hauv huab cua txias. Hauv qab no yog cov txheej txheem ntawm kev tsim cov hlau nplaum.

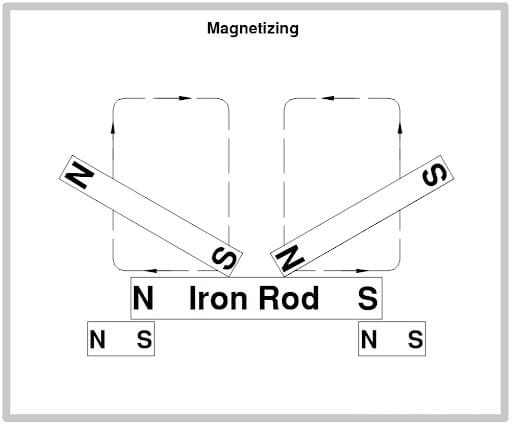

Txhua yam tseem ceeb thiab tseem ceeb ntawm kev xaiv cov hlau nplaum yuav tsum raug coj los sib tham nrog ob pawg engineering thiab ntau lawm. Cov txheej txheem magnetizing ntawm kev tsim cov txheej txheem ntawm cov hlau nplaum, rau qhov no, cov khoom siv yog ib qho ntawm cov hlau compressed. Txawm hais tias nws tau raug xa mus rau lub zog sib nqus thaum lub sij hawm cov txheej txheem ntawm isostatic nias, lub zog tsis coj cov nyhuv sib nqus rau cov khoom, nws tsuas yog lined li cov hmoov xoob. Cov khoom yog coj los ntawm tus ncej ntawm ib tug muaj zog electromagnet thiab tom qab ntawd oriented nyob rau hauv cov kev taw qhia ntawm magnetization. Tom qab lub electromagnet yog energized, lub magnetic quab yuam aligns cov magnetic domains nyob rau hauv cov khoom, ua rau cov khoom ib tug heev ruaj khov hlau nplaum.

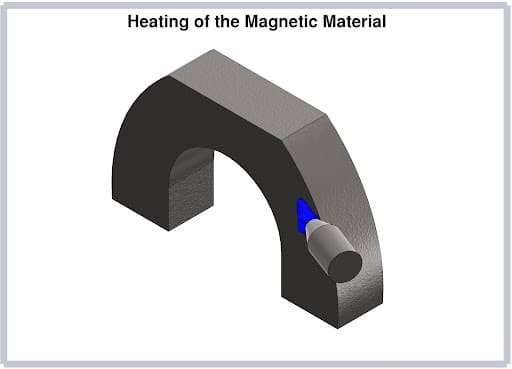

Cua sov ntawm cov khoom

Tom qab cov txheej txheem ntawm isostatic compaction lub slug ntawm cov hmoov hlau yog cais tawm ntawm qhov tuag thiab muab tso rau hauv qhov cub. Sintering yog txheej txheem los yog txoj kev ntawm kev ntxiv cua sov rau compressed hmoov hlau nyob rau hauv thiaj li yuav hloov lawv mus rau hauv fused, khoom hlau tej daim tom qab.

Cov txheej txheem sintering feem ntau muaj peb theem. Thaum lub sij hawm thawj theem txheej txheem, cov khoom siv compressed yog rhuab ntawm qhov kub thiab txias heev kom tshem tawm tag nrho cov ya raws los yog tag nrho cov khoom tsis huv uas yuav tau nkag mus rau hauv cov txheej txheem isostatic compaction. Thaum lub sij hawm sintering thib ob theem, muaj qhov kub thiab txias txog li 70-90% ntawm cov hlau melting point. Tom qab ntawd qhov kub thiab txias yog nyob rau hauv qhov chaw ntawm ib teev los yog hnub nyob rau hauv thiaj li yuav ua rau cov khoom me me kom phim, khi thiab fuse ua ke. Qhov kawg theem ntawm sintering yog thaum cov khoom yog txias heev maj mam nyob rau hauv kev tswj kub increments.

Annealing ntawm cov khoom

Tom qab cov txheej txheem cua sov los ntawm cov txheej txheem ntawm annealing. Qhov no yog thaum cov khoom siv sintered dhau mus rau lwm cov kauj ruam los ntawm kev tswj cov cua sov thiab cua txias kom tshem tawm ib qho lossis tag nrho cov kev ntxhov siab uas nyob hauv cov khoom thiab ua kom nws muaj zog.

Magnet Finishing

Cov hlau nplaum sintered saum toj no suav nrog qee qib lossis qib ntawm kev ua haujlwm, xws li kev sib tsoo lawv du thiab sib luag lossis tsim cov khoom me me tawm ntawm cov hlau nplaum thaiv. Cov khoom siv hlau nplaum yog qhov nyuaj thiab nkig (Rockwell C 57 txog 61). Yog li cov khoom siv no xav tau pob zeb diamond log rau cov txheej txheem slicing, lawv kuj tau siv rau cov log abrasive rau cov txheej txheem sib tsoo. Cov txheej txheem ntawm slicing yuav ua tau nrog zoo precision thiab feem ntau tshem tawm qhov xav tau rau cov txheej txheem ntawm kev sib tsoo. Cov txheej txheem saum toj no yuav tsum tau ua kom zoo zoo txhawm rau txhawm rau txo qhov chipping thiab tawg.

Muaj cov rooj plaub uas cov hlau nplaum kawg los yog cov duab zoo heev rau kev ua haujlwm nrog lub pob zeb diamond sib tsoo log zoo li lub khob cij. Qhov kawg tshwm sim nyob rau hauv cov duab kawg yog coj mus rau yav dhau los lub sib tsoo log thiab lub sib tsoo log muab qhov tseeb thiab meej qhov ntev. Cov khoom annealed yog li ze rau cov duab tiav thiab qhov ntev uas nws xav tau los ua. Ze net zoo yog lub npe uas feem ntau muab rau tus mob no. Cov txheej txheem machining kawg thiab zaum kawg tshem tawm cov khoom siv ntau dhau thiab nthuav tawm qhov chaw du heev thaum xav tau. Thaum kawg txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm

Magnetizing txheej txheem

Magnetizing ua raws cov txheej txheem tiav, thiab thaum tsim cov txheej txheem ua tiav, cov hlau nplaum xav tau them nyiaj txhawm rau tsim cov khoom sib nqus sab nraud. Yuav kom ua tiav qhov no, solenoid yog siv. Lub solenoid yog lub tog raj kheej hollow rau hauv qhov sib txawv ntawm cov hlau nplaum sib txawv thiab cov duab tuaj yeem muab tso rau lossis nrog cov khoom siv lub tshuab solenoid yog tsim los muab ntau cov qauv sib nqus los yog tsim qauv. . Kev txiav txim siab yuav tsum tau ua raws li qhov xav tau ntawm magnetizing teb, uas yog qhov tseem ceeb heev.

Lub sij hawm xa tuaj: Plaub Hlis-05-2022