Sib Nqus Lim Bar

Lub tshuab lim hlau nplaum yog ib qho cuab yeej siv los ntxuav cov impurities ntawm cov kua thiab roj. Cov cuab yeej no feem ntau muaj ib lossis ntau cov hlau nplaum uas ntes thiab lim impurities hauv cov kua lossis roj kab los tiv thaiv cov cuab yeej los ntawm kev puas tsuaj.

Sib nqus lim rods tuaj yeem lim dej, roj, hmoov thiab cov khoom siv zoo heev. Txawm hais tias nws kho dej, roj, roj lossis hmoov txhuv nplej siab, iav, minerals, thiab lwm yam, nws tuaj yeem tau txais txiaj ntsig zoo.

Sib nqus lim rods muaj kev pom zoo. Vim nws cov khoom sib nqus adsorption, nws tuaj yeem lim tawm cov impurities me me zoo, yog li txhim kho qhov zoo thiab purity ntawm cov khoom.

Sib nqus lim rods yog yooj yim los ntxuav, tswj thiab hloov. Vim nws cov qauv yooj yim, nws tuaj yeem yooj yim disassembled thiab ntxuav kom muaj kev siv zoo. Yog hais tias nws yuav tsum tau hloov, tsuas yog hloov lub magnetic filter bar.

Sib nqus lim rods yog kev lag luam thiab siv tau. Piv nrog rau cov lim dej ib txwm siv, cov hlau nplaum hlau nplaum yuav tsum tsis muaj lub zog ntxiv lossis tus nqi thiab tuaj yeem ua cov haujlwm pom tau sai thiab ua tau zoo, yog li txo cov nqi tsim khoom thiab nce kev tsim khoom.

Magnetic Filter Bar Specifications

Loj: Qhov loj ntawm cov hlau nplaum hlau nplaum yuav tsum raug xaiv raws li qhov loj ntawm cov kav dej thiab cov dej ntws. Qhov loj yog feem ntau piav qhia los ntawm qhov tsis xws li qhov ntev thiab txoj kab uas hla.

| Yam khoom No. | Txoj kab uas hla (mm) | Ntev (mm) | Nto Flux (Gaus) | Yam khoom No. | Txoj kab uas hla (mm) | Ntev (mm) | Nto Flux (Gaus) |

| 25 × 100 | 25 | 100 | 1500-14000 AWG | 25 × 600 hli | 25 | 600 | 1500-14000 AWG |

| 25 × 150 hli | 25 | 150 | 1500-14000 AWG | 25 × 650 hli | 25 | 650 | 1500-14000 AWG |

| 25 × 200 | 25 | 200 | 1500-14000 AWG | 25 × 700 hli | 25 | 700 | 1500-14000 AWG |

| 25 × 250 hli | 25 | 250 | 1500-14000 AWG | 25 × 750 hli | 25 | 750 | 1500-14000 AWG |

| 25 × 300 hli | 25 | 300 | 1500-14000 AWG | 25 × 800 hli | 25 | 800 | 1500-14000 AWG |

| 25 × 350 hli | 25 | 350 | 1500-14000 AWG | 25 × 850 hli | 25 | 850 | 1500-14000 AWG |

| 25 × 400 hli | 25 | 400 | 1500-14000 AWG | 25 × 900 hli | 25 | 900 | 1500-14000 AWG |

| 25 × 450 hli | 25 | 450 | 1500-14000 AWG | 25 × 950 hli | 25 | 950 ua | 1500-14000 AWG |

| 25 × 500 hli | 25 | 500 | 1500-14000 AWG | 25 × 1000 hli | 25 | 1000 | 1500-14000 AWG |

| 25 × 550 hli | 25 | 550 | 1500-14000 AWG | 25 × 1500 hli | 25 | 1500 | 1500-14000 AWG |

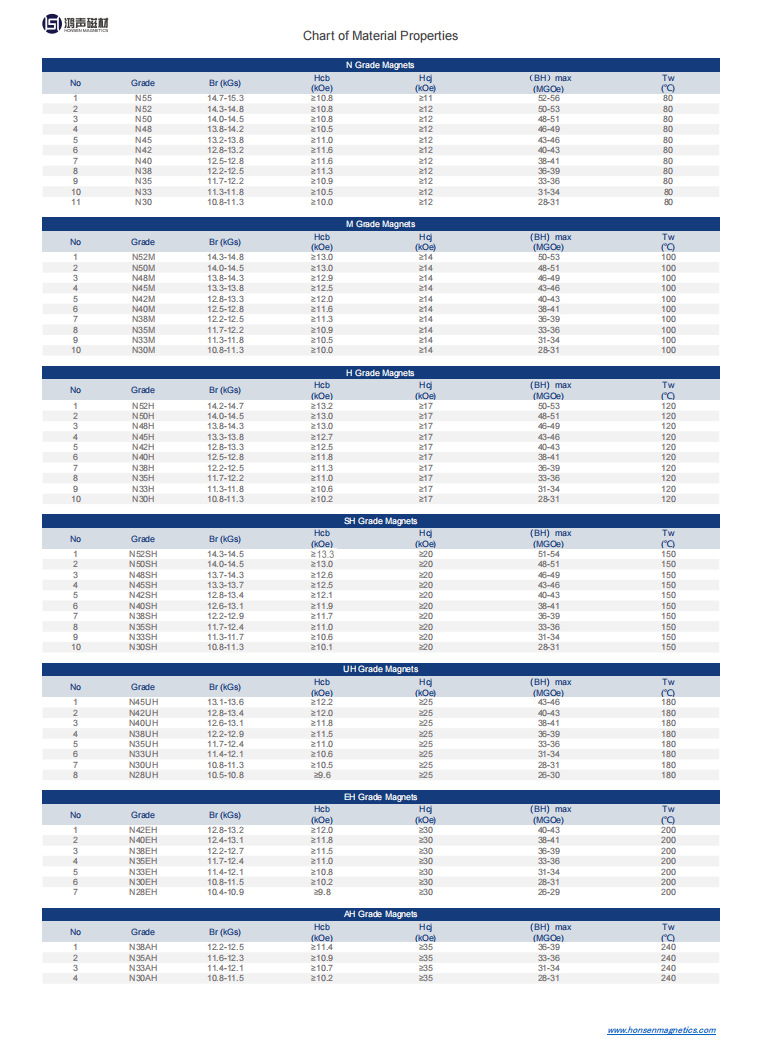

Kub: Cov khoom siv thiab vaj tse ntawm lub tshuab lim hlau nplaum yuav tsum tuaj yeem tiv taus qhov kub siab lossis qis ntawm nws qhov chaw thov.

| Qib | Max. ua haujlwm Temp | Curie Temp | Txhawb kev sib nqus qib |

| N | 80 ℃ / 176 ℉ | 310 ℃ / 590 ℉ | N30-N55 |

| M | 100 ℃ / 212 ℉ | 340 ℃ / 644 ℉ | N30M-N52M |

| H | 120 ℃ / 248 ℉ | 340 ℃ / 644 ℉ | N30H-N52H |

| SH | 150 ℃ / 302 ℉ | 340 ℃ / 644 ℉ | N30SH-N52SH |

| UH | 180 ℃ / 356 ℉ | 350 ℃ / 662 ℉ | N28UH-N45UH |

| Eh | 200 ℃ / 392 ℉ | 350 ℃ / 662 ℉ | N28EH-N42EH |

| AH | 240 ℃ / 464 ℉ | 350 ℃ / 662 ℉ | N30AH-N38AH |

Curie Temp: tseem hu ua Curie point lossis magnetic transition point, yog qhov theoretical ua haujlwm kub txwv ntawm cov khoom sib nqus, dhau ntawm Curie kub, cov khoom sib nqus ntawm cov khoom sib nqus yuav ploj mus.

Max.working Temp: Yog tias qhov siab tshaj plaws ua haujlwm kub siab tshaj, cov hlau nplaum ntawm cov khoom sib nqus yuav raug demagnetized thiab irreversible poob yuav tshwm sim.

Kev sib raug zoo: qhov kub ntawm Curie ntau dua, qhov siab dua qhov ua haujlwm kub ntawm cov khoom siv, thiab qhov zoo dua qhov kub thiab txias.

Magnetic force: Lub zog sib nqus ntawm lub tshuab nqus hlau nplaum nyob ntawm hom thiab cov hlau nplaum hauv nws. Lub zog sib nqus muaj zog tuaj yeem txhim kho qhov pom kev ua haujlwm zoo tab sis kuj tseem tuaj yeem cuam tshuam tus nqi ntws ntawm cov kua lossis roj.

Khoom siv: Cov khoom siv ntawm cov hlau nplaum lim dej yuav tsum sib haum nrog cov kua lossis roj lim thiab yuav tsum tsis txhob raug corrosion.

Vim nws zoo heev corrosion kuj, stainless hlau yog cov khoom siv feem ntau siv hauv ntau daim ntawv thov. Txawm li cas los xij, rau cov ntawv thov uas xav tau qib siab dua ntawm kev tiv thaiv corrosion, nws yog ib qho tseem ceeb rau xaiv cov qib siab dua ntawm cov khoom siv stainless hlau. Piv txwv suav nrog 316 lossis 316L, uas tshwj xeeb tshaj yog tsim rau kev lag luam xws li cov khoom noj lossis tshuaj ua haujlwm, qhov chaw raug tshuaj hnyav lossis cov av noo siab tuaj yeem tshwm sim.

Yog tias koj tsis paub meej tias cov ntaub ntawv twg yog qhov zoo tshaj plaws rau koj qhov kev thov tshwj xeeb, thov hu rau peb. Peb pab pawg kws tshaj lij tuaj yeem muab cov lus qhia thiab kev taw qhia rau koj los pab koj txiav txim siab. Ntawm Honsen, peb tau cog lus los xyuas kom meej tias koj tau txais cov khoom zoo tshaj plaws rau koj daim ntawv thov, thiab peb ib txwm nyob ntawm no los pab.

Kev teeb tsa:

Qhov kawg ntawm cov hlau nplaum muaj cov txiv neej threads

Qhov kawg ntawm cov hlau nplaum muaj cov poj niam threads

Qhov kawg ntawm cov hlau nplaum yog tiaj welded

Ob qhov kawg ntawm cov hlau nplaum tuaj yeem ua kev cai mounted kom tau raws li koj cov kev xav tau tshwj xeeb, nrog rau kev xaiv xws li txiv neej, poj niam, thiab tiaj tus weld. Txawm koj xav tau dab tsi, peb tuaj yeem muab cov hlau nplaum zoo los xyuas kom muaj txheej txheem kev teeb tsa seamless.

Yuav ua li cas xaiv txoj cai magnetic filter bar?

Flow rate: Txiav txim siab tus nqi ntws thiab kev khiav hauj lwm kub uas yuav tsum tau lim. Qhov no yuav pab txiav txim seb yuav tsum muaj pes tsawg tus hlau nplaum lim rods thiab hom hlau nplaum lim rods.

Magnetic zog: Xaiv qhov tsim nyog lub zog sib nqus raws li hom thiab qhov loj ntawm impurities yuav raug tshem tawm. Feem ntau, cov hlau nplaum hlau nplaum yuav tsum muaj zog dua rau cov khoom me me.

Puab: Xaiv qhov tsim nyog sib nqus lim bar duab raws li qhov tseeb qhov chaw teeb tsa thiab cov khoom siv ntawm lub lim.

Khoom siv: Xaiv cov ntaub ntawv tsim nyog kom haum cov kua dej sib txawv thiab ib puag ncig, xws li stainless hlau, titanium alloy, khoom siv hlau nplaum ruaj khov, thiab lwm yam.

Lub neej thiab kev saib xyuas tus nqi: Xaiv cov hlau nplaum hlau nplaum nrog lub neej ntev thiab kev saib xyuas qis kom txo tau cov nqi siv thiab kev saib xyuas.

Daim ntawv thov ntawm magnetic filter bar

Kev lag luam yas: Cov hlau nplaum hlau nplaum feem ntau yog siv rau hauv cov cua txias ntawm kev txhaj tshuaj molding tshuab, extruders, tshuab moulding tshuab thiab lwm yam khoom siv los tshem tawm cov hlau chips, hlau hmoov thiab lwm yam impurities los tiv thaiv kev ua haujlwm ntawm cov khoom siv.

Kev lag luam kws tshuaj: cov hlau nplaum hlau nplaum tuaj yeem tshem tawm cov impurities xws li hlau chips thiab steel spikes los ntawm cov kua tshuaj los xyuas kom meej cov purity thiab zoo ntawm cov tshuaj.

Kev lag luam khoom noj khoom haus: Cov hlau nplaum hlau nplaum yog siv dav hauv cov khoom noj khoom haus kom tshem tawm cov hlau impurities hauv cov khoom noj kom ntseeg tau tias cov khoom zoo thiab kev nyab xeeb.

Kev lag luam machining: Sib nqus lim rods feem ntau yog siv rau hauv tshuab cuab yeej coolant kom tshem tawm cov hlau chips, xuab zeb thiab lwm yam impurities kom ntev lub neej thiab txhim kho machining raug.

Kev lag luam roj: Cov hlau nplaum hlau nplaum tuaj yeem tshem tawm cov chips hlau thiab lwm yam impurities hauv cov pa roj thiab cov roj liquefied los tiv thaiv kev ua haujlwm zoo ntawm cov khoom siv roj.

Kev lag luam tshuaj: Nws yog siv los tshem tawm ferromagnetic hais thiab oxides tshem tawm hauv cov tshuaj.

Kev lag luam ntawv: siv los tshem tawm ferromagnetic impurities nyob rau hauv cov txheej txheem papermaking los xyuas kom meej cov ntawv zoo.

Kev lag luam mining: siv los cais cov zaub mov uas muaj hlau los ntawm ore thiab txhim kho kev ua haujlwm ntawm cov ntxhia.

Kev lag luam kev kho dej: sib nqus lim rods thiab tuav yog cov cuab yeej zoo rau kev tshem tawm cov hlau, manganese thiab lwm yam hlau los ntawm dej, ua rau nws muaj kev nyab xeeb rau kev haus thiab lwm yam kev siv.

Kev lag luam textile: Sib nqus lim rods thiab tuav yog siv rau hauv kev tsim textile kom tshem tawm cov kab mob hlau los ntawm cov ntaub, ua kom cov khoom zoo thiab tiv thaiv kev puas tsuaj rau cov tshuab.

Automotive kev lag luam: Sib nqus lim rods yog siv nyob rau hauv automotive manufacturing kom tshem tawm cov hlau paug ntawm coolant thiab lubricants los tiv thaiv kev puas tsuaj rau cov khoom thiab xyuas kom meej cov khoom zoo.

Peb Qhov Zoo

Nrhiav lub zoo meej round magnetic lim bar rau koj xav tau kev pab! Peb cov pas nrig sib nqus muaj nyob rau hauv kev thov.

1.Our magnetic lim rods thiab tuav yog tsim los ntawm cov khoom zoo stainless hlau tubing thiab tuaj nrog kev ua haujlwm siab neodymium hlau nplaum kom haum rau koj daim ntawv thov tshwj xeeb. Siv ib tus neeg sib nqus lim rods, koj tuaj yeem tsim lossis hloov koj tus kheej cov khoom sib nqus sib cais.

2.Xaiv lub zog sib nqus uas haum rau koj xav tau! Peb cov khoom muaj nyob rau hauv magnetic zog los ntawm 1500-14000 gauss kom tau raws li koj cov kev cai tshwj xeeb. Bars nruab nrog cov hlau nplaum neodymium muaj zog tuaj yeem muaj qhov muaj txiaj ntsig sib nqus mus txog 14,000 gauss ntawm lawv qhov chaw.

3.A zoo meej haum rau peb cov ntsaws ruaj ruaj thiab welded pas nrig! Peb muab customizable txiv neej, poj niam los yog ca welded xaus kom tau raws li koj cov kev cai.

4.Tag nrho peb cov khoom sib nqus yog cov dej tsis muaj dej, kom ntseeg tau tias lawv ua haujlwm tau zoo txawm tias nyob hauv qhov chaw ntub dej lossis ntub dej.

5.Our magnetic filter bars thiab rods yog zoo polished los muab ib tug kws tsos thiab xyuas kom meej lawv yooj yim los ntxuav thiab tswj.

Nrog peb cov ntaub ntawv zoo thiab cov kev xaiv yooj yim, koj tuaj yeem ntseeg siab tsim lossis hloov kho koj tus kheej cov khoom sib nqus sib nqus.

Post lub sij hawm: Apr-13-2023