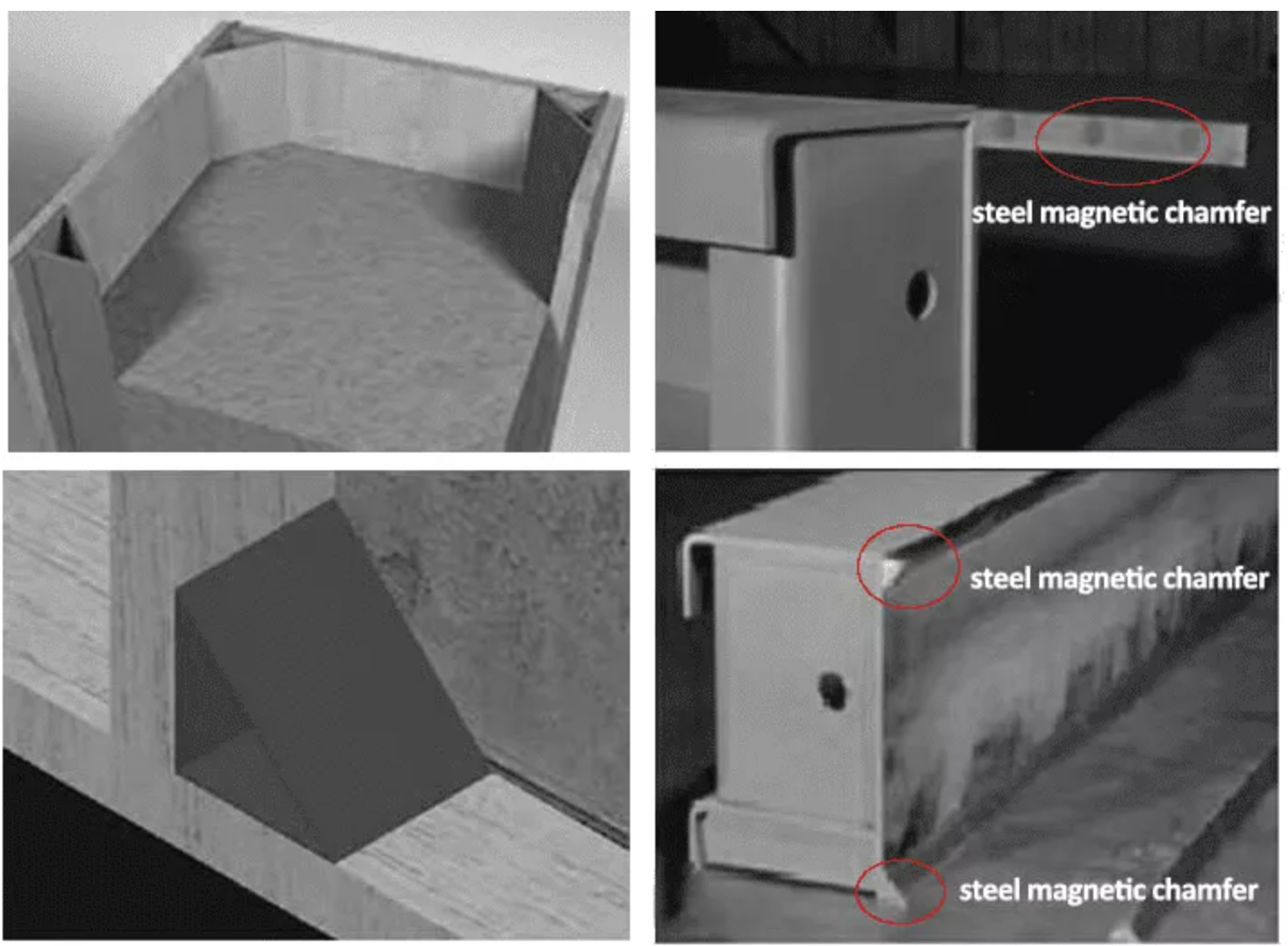

Kev siv cov hlau nplaum hlau chamfer strips tau siv dav hauv kev lag luam precast pob zeb rau xyoo lawm. Cov khoom siv ruaj khov no yog tsim los tiv thaiv kev ua haujlwm hnyav thiab feem ntau siv los tuav cov hlau kom ruaj ntseg. Nws lub hom phiaj tseem ceeb yog los tsim cov npoo beveled ntawm cov ces kaum ntawm cov pob zeb ua ke, thiab qee qhov kev siv formwork.

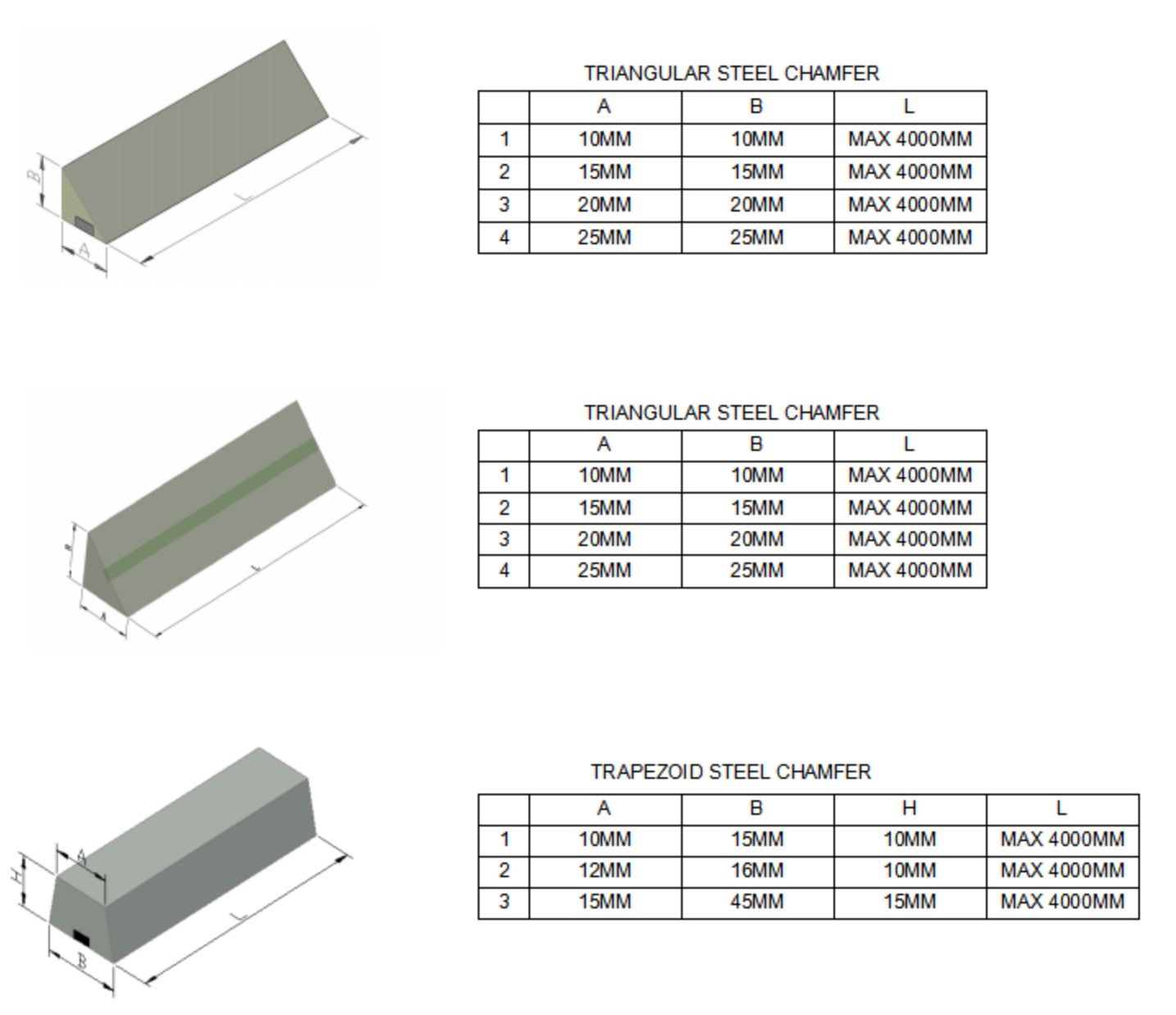

Ob daim duab ntau tshaj plaws rau cov hlau nplaum no yog daim duab peb sab thiab trapezoids. Sib nqus strips tau dhau los ua ib qho ntawm ntau yam khoom siv hauv kev lag luam precast pob zeb. Cov neeg tsim khoom tuaj yeem xaiv los ntawm ntau qhov ntau thiab tsawg thiab muaj kev xaiv los hloov kho cov strips kom tau raws li lawv cov kev xav tau tshwj xeeb. Lub versatility ntawm cov strips no txuas mus rau lawv compatibility nrog ntau yam kev ua vaj tse, kom ntseeg tau ntau yam kev siv. Ntxiv rau nws txoj haujlwm, cov hlau nplaum hlau nplaum kuj muaj ntau yam zoo.

Ua ntej, lawv muab cov adhesion muaj zog vim lawv cov khoom sib nqus, ua rau muaj kev sib txuas ntawm cov pob zeb thiab cov hlau. Qhov thib ob, cov strips no muab cov nqi thiab sijhawm ua haujlwm tau zoo. Lawv yooj yim installation thiab tshem tawm cov txheej txheem txuag lub sij hawm tseem ceeb thaum lub sij hawm tsim kho, yog li txo cov nqi zog.

Tsis tas li ntawd, lawv cov xwm txheej rov siv tau tshem tawm qhov xav tau hloov pauv raws sijhawm, txuag cov nqi mus sij hawm ntev. Lwm qhov tseem ceeb ntawm cov hlau nplaum no yog lawv qhov sib xws nrog cov qauv tsim vaj tsev sib txawv. Lawv sib xyaw seamlessly rau hauv ntau yam precast qhob vaj tse, txhim kho qhov zoo nkauj ntawm cov khoom kawg.

Cov strips no xyuas kom meej thiab meej chamfered npoo rau polished thiab kev ua tiav. Sib nqus hlau chamfer strips ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev ncaj ncees ntawm cov khoom siv precast. Los ntawm kev tsim cov npoo beveled, lawv txo qhov kev pheej hmoo ntawm chipping thiab muab kev cuam tshuam ntau dua. Qhov no ua rau kom cov kav ntev thiab ntev ntawm cov qauv precast pob zeb, ua kom nws ruaj khov thiab ua haujlwm tau zoo rau xyoo tom ntej.

Sib nqus hlau chamfering sawb tau dhau los ua ib qho khoom siv tseem ceeb hauv kev lag luam precast pob zeb. Lawv muaj peev xwm tiv taus cov xwm txheej hnyav, lawv qhov ntau yam ntawm qhov loj thiab kev hloov kho, thiab lawv cov txiaj ntsig ntau ua rau lawv yog ib feem tseem ceeb ntawm kev tsim cov vaj tsev zoo precast. Nrog rau lawv cov adhesion muaj zog, tus nqi thiab lub sij hawm efficiency, compatibility nrog lub tsev tsim, thiab kev koom tes rau structural kev ncaj ncees, cov hlau nplaum no tseem ua lub luag haujlwm tseem ceeb hauv kev tsim kho kev lag luam.

Xaiv ib sab chamfers thaum koj koom nrog steel nto ib zaug, xws li cov rooj steel lossis panels. Thaum ua hauj lwm nrog ob seem steel uas nyob ib sab, xaiv ob-sided chamfering los xyuas kom meej qhov chaw ruaj ntseg ntawm ob qhov chaw.

Khoom siv: Roj Hmab, Q215, Q235 Hlau Yam, Neodymium Magnets

Kev kho deg: Magnet Zn lossis NiCuNi Txheej

Max ua haujlwm kub: 80 ℃

Reusability thiab kav ntev ntev;

Cov khoom sib nqus encased nyob rau hauv steel muab tsis tshua muaj siab adhesion;

Txhim kho cov txiaj ntsig thiab qhov zoo ntawm cov phab ntsa precast qhob yooj yim tuav tsis muaj hlau nplaum rub thaum siv niaj hnub;

Tshem tawm cov trenches uas yuav tsum tau ua pob zeb;

Qhov chaw ceev thiab yooj yim, tshem tawm thiab tu Precise positioning on the formwork without screws, bolts or welding, zam kev puas tsuaj rau lub formwork rooj;

Tsim kom haum seamlessly nrog steel txaj, steel panels thiab txhua hom precast rail thav duab;

Piv nrog cov tsoos chamfering ncej, muaj zog suction kom ntseeg tau tias chamfering ncej yuav tsis txav thaum lub sij hawm watering;

Ib qho yooj yim expansion, standardization thiab loj ntau lawm.

- Txawm hais tias qhov nqus ntawm chamfer strips tsis muaj zog npaum li cov hlau nplaum, nws tseem muaj qhov nqus zoo. Kev siv tsis raug yuav ua rau tus kheej raug mob, puas tsuaj rau cov hlau nplaum, lossis kev puas tsuaj rau qhov chaw ua haujlwm. Thaum peb cov hlau nplaum hlau nplaum yog cov neeg siv-phooj ywg, noj ob peb qhov kev ceev faj ntxiv yuav tsis tsuas yog tiv thaiv koj xwb tab sis lub chamfer nws tus kheej. Hauv qab no, peb nthuav tawm cov lus pom zoo txog kev nyab xeeb ua ntej, thaum, thiab tom qab siv.

- Tsis txhob tso lub chamfer ntsug raws li lub zog ntawm qhov cuam tshuam yuav ua rau cov hlau nplaum tawg. Xwb, muab lub chamfer pas nrig rau ntawm ib sab ua ntej, ces maj mam muab tso rau hauv qhov chaw.

- Txawm hais tias cov hlau nplaum thiab cov hlau raug kho los tiv thaiv xeb, tsis tu ncua tsis tu ncua tuaj yeem ua rau cov cement lo rau chamfer strips, ua rau lawv nyuaj rau tshem tawm. Txhawm rau ua kom lub neej ntev ntawm koj lub chamfer, ntxuav nws tom qab siv txhua zaus thiab siv cov roj los tiv thaiv xeb kom nws ua haujlwm zoo tshaj plaws.

- Xyuas kom tseeb tias qhov siab tshaj plaws kev khiav hauj lwm los yog cia kub qis dua 80 ° C. Qhov ntsuas kub siab tuaj yeem ua rau cov kab nrib pleb kom tsis muaj zog lossis ploj tag nrho lawv cov hlau nplaum.

- Khaws nws deb ntawm cov khoom siv hluav taws xob (xws li xov tooj ntawm tes, laptops, ntsiav tshuaj, thiab khoos phis tawj) thiab cov hlau tsis tsim nyog ferromagnetic.

- Siv ceev faj heev thaum siv chamfers ze cov neeg uas muaj pacemakers. Daim duab peb sab steel chamfer tsim ib qho chaw sib nqus muaj zog heev uas tuaj yeem cuam tshuam nrog cov khoom siv hluav taws xob hauv lub tshuab pacemaker.

- Yog tias muaj pob zeb lossis cov khib nyiab daig rau hauv chamfer, tshem tawm tam sim ntawd. Rau cov pob zeb tawv tawv, maj mam txhuam los yog txhuam lawv.

- Nco ntsoov khaws cov pwm rooj saum npoo du. Yog tias muaj ib qho khoom tawv tawv ntawm cov hlau nplaum thiab cov pwm pwm, qhov nqus dej muaj zog tuaj yeem ua rau cov hlau nplaum deform.

- Ib txwm tuav daim duab peb sab chamfers nrog kev saib xyuas. Thaum koj ua tiav, teeb tsa me me kom tiv thaiv kev sib tsoo lossis yuam kev pinching koj txhais tes thiab ntiv tes.

- Peb pom zoo kom khaws cov chamfers ntawm cov yas lossis roj hmab sawv ntsug kom yooj yim nkag mus.

- Tsis txhob raug tshav ntuj ntev vim qhov kub thiab txias yuav ua rau cov hlau nplaum tsis muaj zog lossis ua tiav degaussing ntawm cov hlau nplaum chamfers.

- Khaws tej chaw huv si. Txawm hais tias ob qho tib si cov hlau nplaum thiab cov hlau raug kho los tiv thaiv xeb, tsis ua kom huv ntawm cov hlau nplaum kom txaus tuaj yeem ua rau cov cement lo rau ntawm chamfer sawb, ua rau nws nyuaj rau tshem tawm. Yog li ntawd, cov neeg siv tau pom zoo kom ntxuav thiab roj tom qab siv txhua zaus. Txawm hais tias xeb-resistant txheej ntawm steel nto, pob zeb yog alkaline thiab corrosive, uas tuaj yeem ua rau corrosion ntawm steel nto lub sij hawm.

Tsim muaj tshaj kaum xyoo dhau los,Honsen Sib Nqusyog ib lub npe zoo nyob rau hauv daim teb ntawm cov hlau nplaum ruaj khov thiab cov khoom sib nqus tsim thiab muag. Peb pab neeg muaj kev paub dhau los saib xyuas tag nrho cov voj voog ntau lawm, suav nrog kev siv tshuab, sib dhos, vuam, thiab txhaj tshuaj molding. Peb cov khoom tau txais txiaj ntsig txawv teb chaws tshwj xeeb tshaj yog nyob hauv Europe thiab Amelikas rau lawv cov nqi sib tw, zoo heev, thiab peb txoj kev cog lus tsis txaus ntseeg rau cov neeg siv khoom-centric.

- Ntau tshaj10 xyoo kev paub hauv kev lag luam magnetic khoom ruaj khov

- Tshaj5000 m2 Hoobkas yog nruab nrog200Cov tshuab siab heev

- Muaj ibua tiav cov kab ntau lawmlos ntawm machining, assembling, vuam, txhaj tshuaj molding

- Muaj pab pawg R & D muaj zog tuaj yeem muab tau zooOEM & ODM kev pabcuam

-Cov neeg ua haujlwm txawj & kev txhim kho tsis tu ncua

- Kev xa khoom sai & xa khoom thoob ntiaj teb

- Ua haujlwmONE-STOP-SOLUTION xyuas kom muaj txiaj ntsig & raug nqi yuav khoom

- Ua haujlwm nrog cov neeg siv khoom loj & me metsis muaj MOQ

Peb tau cog lus los muab kev pabcuam rau yav tom ntej thiab muaj tswv yim, cov khoom sib tw, thiab peb lub hom phiaj yog los txhawb peb txoj haujlwm ua lag luam. Tsav los ntawm kev nce qib tseem ceeb hauv cov hlau nplaum ruaj khov thiab cov khoom sib txuas, peb tau tsom mus rau kev loj hlob los ntawm kev ua haujlwm thev naus laus zis thiab nkag mus rau kev lag luam tshiab. Coj los ntawm Tus Thawj Kws Ua Haujlwm, peb cov kws tshaj lij R & D tau siv lub peev xwm hauv tsev, ua kom muaj kev sib raug zoo ntawm cov neeg siv khoom, thiab cia siab tias yuav muaj kev lag luam nrog kev pom. Cov pab pawg ywj pheej ceev faj tswj hwm cov haujlwm thoob ntiaj teb thiab tswj hwm kev ua haujlwm tsis tu ncua ntawm kev tshawb fawb.

Kev tswj kom zoo yog lub hauv paus ntawm peb lub tswv yim kev lag luam. Peb suav hais tias qhov zoo yog qhov tseem ceeb thiab kev coj ua ntawm lub tuam txhab. Mus dhau ntawm cov ntaub ntawv nkaus xwb, peb seamlessly integrate peb zoo tswj system rau hauv peb cov txheej txheem. Qhov no ua kom ntseeg tau tias peb cov khoom tsis tu ncua ua tau raws li peb cov neeg siv khoom xav tau, ua kom pom peb txoj kev mob siab rau tus qauv ntawm kev ua tau zoo.

At Honsen Sib Nqus, peb cov hauv paus ntsiab lus tseem ceeb yog ob zaug: ua kom muaj kev paub tshwj xeeb rau cov neeg siv khoom thiab tswj xyuas qhov ntsuas kev nyab xeeb tsis hloov pauv. Cov ntsiab cai no siv tau rau peb pab neeg thiab txhawb kev txhim kho tus kheej. Kev loj hlob ntawm txhua tus neeg ua haujlwm txhawb nqa kev nce qib ntawm peb lub lag luam.