Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev txhaj tshuaj molded nylon hlau nplaum yog lawv cov khoom sib nqus zoo heev, uas yog piv rau cov hlau nplaum sintered. Lawv kuj muaj qhov tshwj xeeb qhov kev ruaj ntseg, kev siv lub zog, thiab kev tiv thaiv corrosion thiab kub variations, ua rau lawv zoo tagnrho rau siv nyob rau hauv hnyav ib puag ncig.

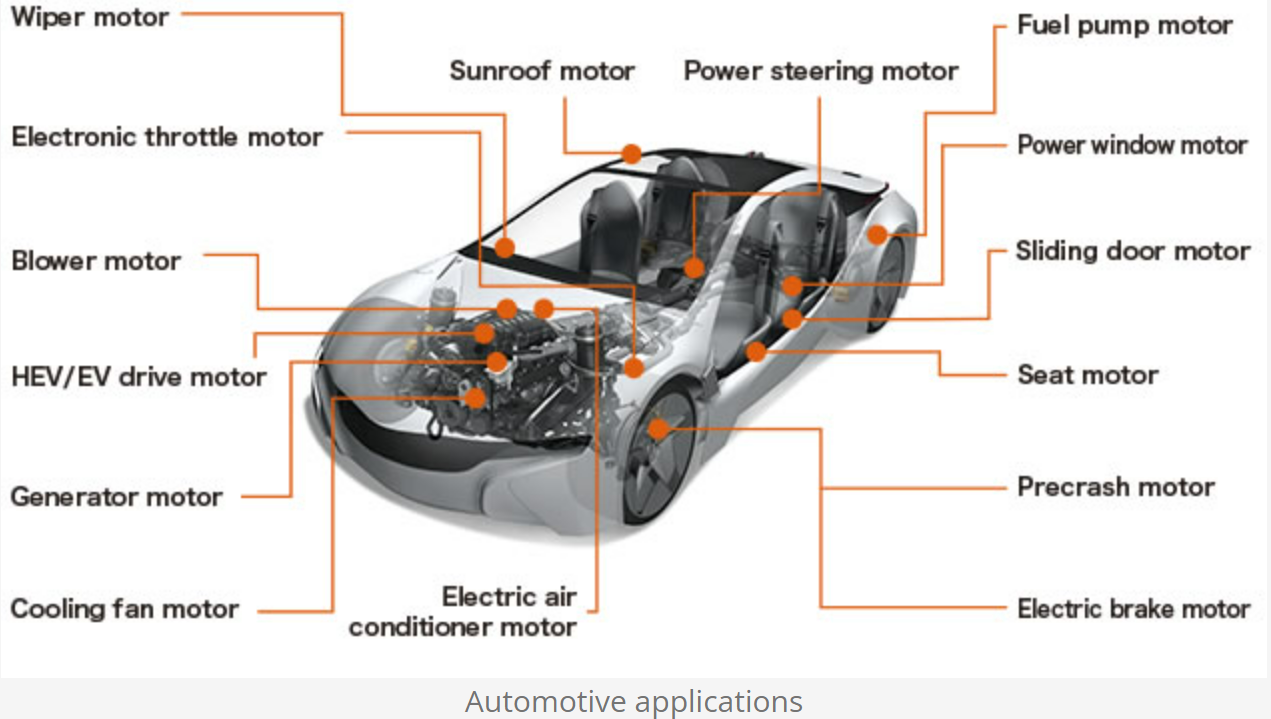

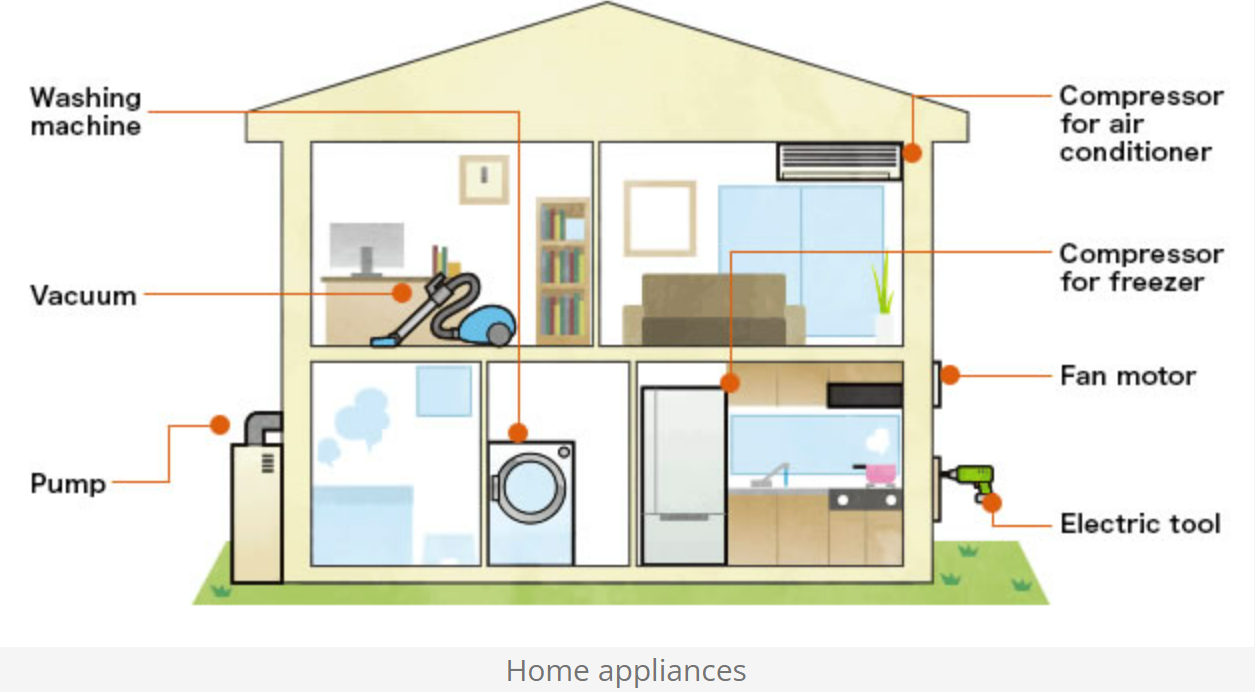

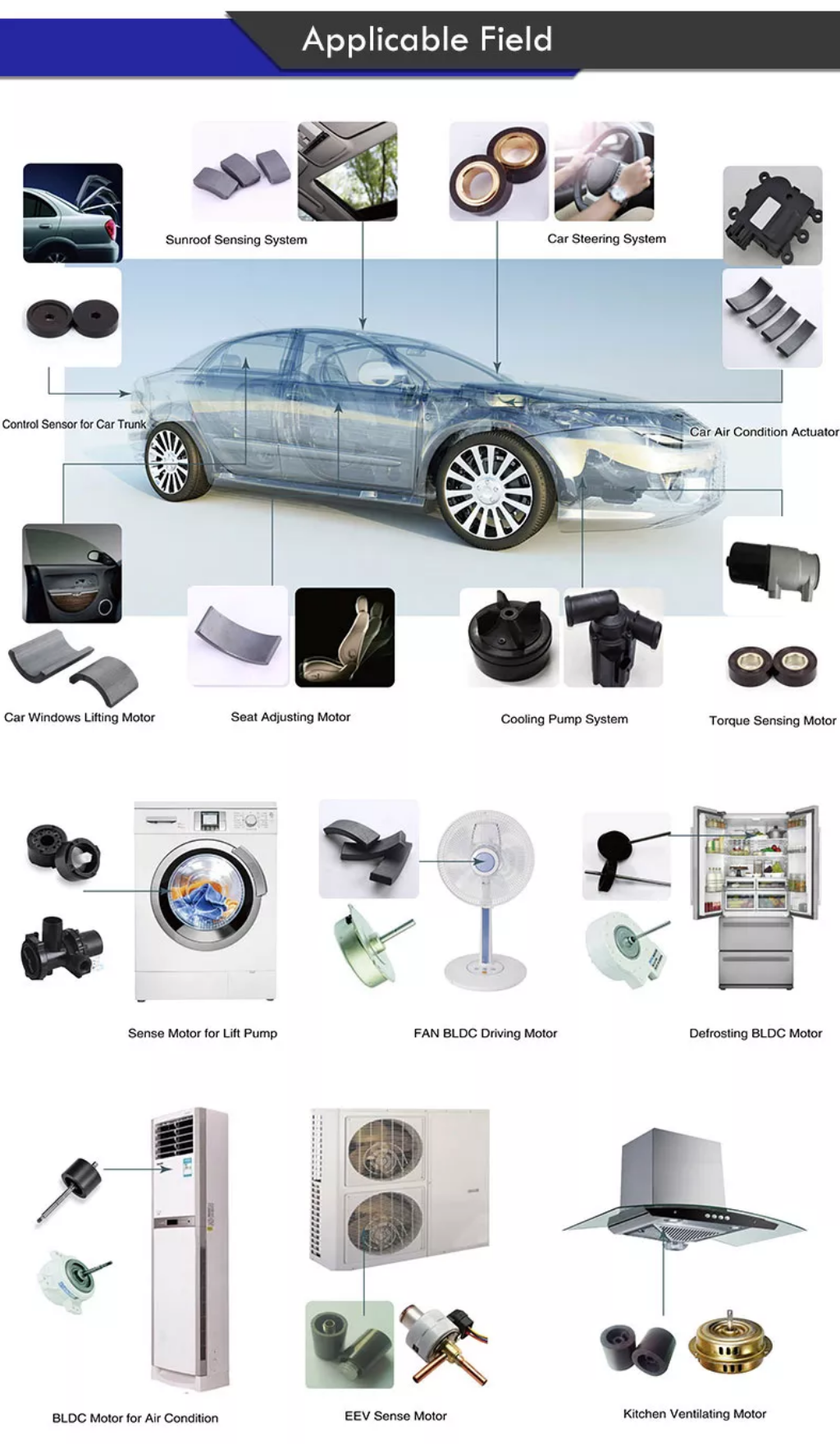

Txhaj tshuaj moulded nylon hlau nplaum tuaj yeem ua rau ntau yam duab thiab ntau thiab tsawg, suav nrog cov duab nyuaj nrog ntau tus ncej thiab cov geometry customized. Qhov no ua rau lawv muaj ntau yam thiab haum rau siv ntau yam kev siv, xws li motors, sensors, actuators, thiab magnetic couplings.

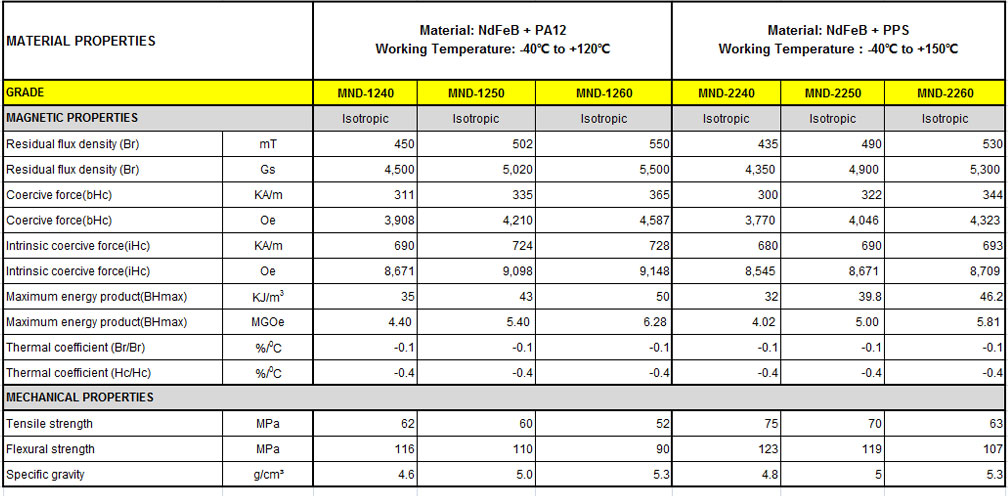

Tsis tas li ntawd, kev txhaj tshuaj molded nylon hlau nplaum tuaj yeem raug kho kom tau raws li cov kev cai tshwj xeeb ntawm cov ntawv thov sib txawv, xws li lub zog sib nqus, qhov kub thiab txias, thiab tiv thaiv demagnetization. Qhov no ua rau lawv hloov tau yooj yim thiab muaj txiaj ntsig zoo rau kev tsim cov khoom sib nqus ua haujlwm siab.

Zuag qhia tag nrho, kev txhaj tshuaj molded nylon hlau nplaum yog cov khoom siv ruaj khov, muaj txiaj ntsig, thiab cov nqi tsim nyog rau kev tsim lub cev muaj zog thiab cov khoom siv hluav taws xob nrog kev ua haujlwm zoo sib nqus thiab qhov ruaj khov. Nrog rau lawv lub peev xwm los tiv thaiv ib puag ncig hnyav thiab raug kho kom tau raws li cov ntawv thov tshwj xeeb, cov hlau nplaum no yog qhov kev xaiv zoo tshaj plaws rau ntau yam kev lag luam.

Performance Table:

Daim ntawv thov: